- 1 Screen Layering: Traditional vs Integrated Approaches

- 2 In‑Cell Technology: Touch Embedded Inside the LCD

- 3 On‑Cell Technology: Touch Placed On the Color Filter Layer

- 4 OGS (One Glass Solution / Touch On Lens)

- 5 Comparative Summary

- 6 Real-World Adoption Examples

- 7 Use Cases and Design Recommendations

- 8 Technical Considerations

- 9 Häufig gestellte Fragen

- 10 Conclusion

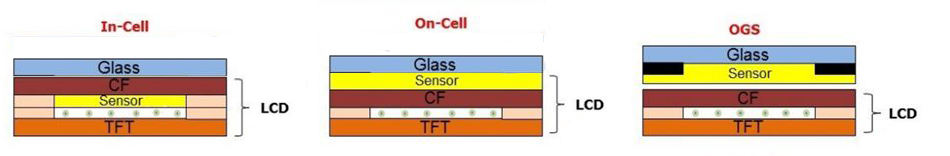

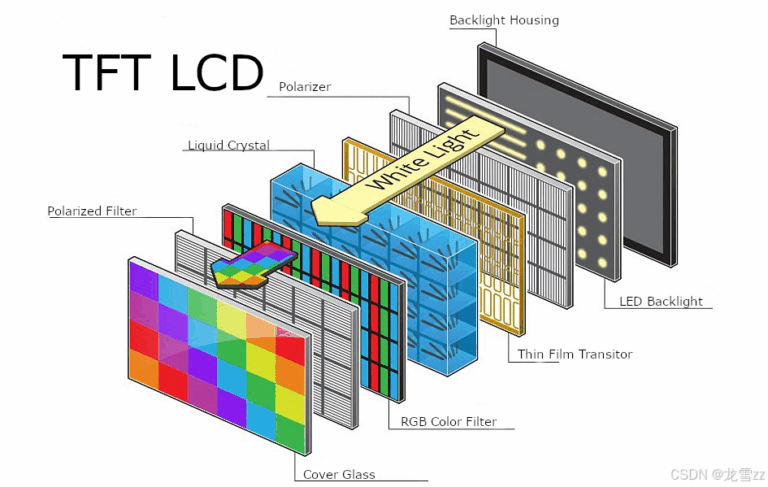

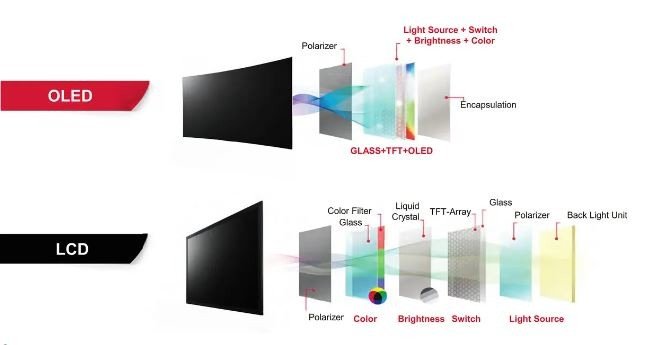

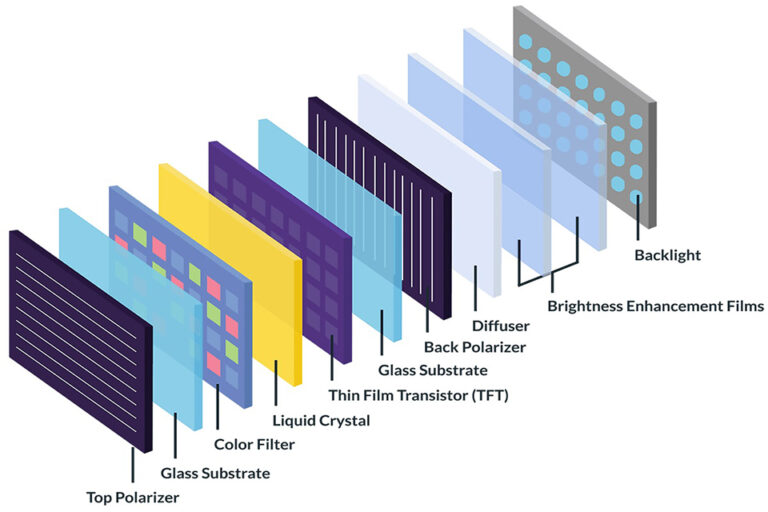

Screen Layering: Traditional vs Integrated Approaches

A typical touchscreen stack includes three layers:

- Cover glass (lens)

- Separate touch sensor layer

- LCD display panel

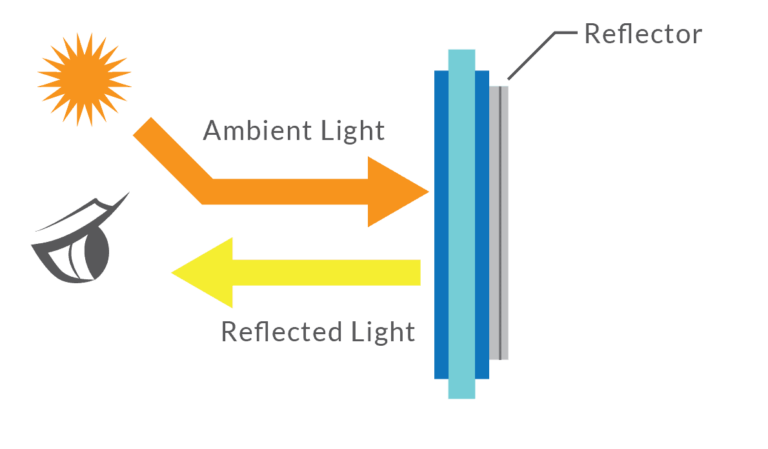

Traditional methods use two bond lines and an air gap between layers, increasing thickness and introducing glare. In contrast, In‑Cell, On‑Cell, and OGS integrate the touch layer into existing components, improving optical performance and reducing weight.

In‑Cell Technology: Touch Embedded Inside the LCD

Definition: Touch sensing electrodes are built directly into the LCD panel—typically at the VCOM or color filter layer.

Wesentliche Merkmale:

- Ultra-thin design with no separate touch layer

- Superior optical clarity with reduced internal reflections

- High integration cost and manufacturing complexity

- Lower yield due to combined touch/display failures

Used in premium devices, In‑Cell technology is ideal where sleek design and visual clarity are prioritized.

On‑Cell Technology: Touch Placed On the Color Filter Layer

Definition: Touch sensors are patterned between the LCD’s color filter and polarizer layers.

Key Attributes:

- Thicker than In‑Cell, but easier to manufacture

- Better impact resistance compared to In‑Cell

- Moderate cost and complexity

- Can cause color non-uniformity under pressure

On‑Cell is common in AMOLED and mid-to-high-end LCDs, balancing performance and feasibility.

OGS (One Glass Solution / Touch On Lens)

Definition: Touch electrodes are deposited directly onto the inner surface of the cover glass, eliminating a separate touch panel.

Benefits:

- Removes one glass and bonding layer, reducing weight and cost

- Offers excellent transparency and touch response

- Lower manufacturing difficulty and better yield

Herausforderungen:

- Requires precise glass processing

- Slightly thicker than In‑Cell, but stronger overall

OGS is widely adopted in smartphones and tablets due to its scalability and visual performance.

Comparative Summary

| Merkmal | In‑Cell | On‑Cell | OGS (Touch-On-Lens) |

|---|---|---|---|

| Thickness | Thinnest | Thin | Mäßig |

| Optical Clarity | Ausgezeichnet | Good | Ausgezeichnet |

| Berührungsempfindlichkeit | Hoch | Moderate–High | Sehr hoch |

| Manufacturing Difficulty | Sehr hoch | Hoch | Niedrig |

| Kosteneffizienz | Lowest | Mäßig | Hoch |

| Dauerhaftigkeit | Mäßig | Hoch | Mäßig |

| Repairability | Niedrig | Niedrig | Medium (glass only) |

Real-World Adoption Examples

- In‑Cell: Used in early Apple iPhones, Nokia Lumia series

- On‑Cell: Adopted in AMOLED smartphones and Microsoft Surface tablets

- OGS: Popular across Xiaomi, Huawei, and other mid-to-high-end mobile devices

Use Cases and Design Recommendations

Wearables & Smartphones:

- Choose In‑Cell or OGS for slim form factors and superior visual performance

Industrial Embedded Systems:

- OGS is ideal for rugged, durable touch interfaces

- On‑Cell is suitable for moderate thickness with good integration

Outdoor Displays & Rugged Devices:

- OGS with hardened glass is most impact-resistant

- Avoid In‑Cell if display failure risk is critical

Technical Considerations

- Touch Noise Interference: In‑Cell and On‑Cell require careful electrical design to avoid signal distortion

- Manufacturing Yield: In‑Cell has higher scrap rates due to tight integration

- Glass Edge Fragility: OGS requires precision cutting to avoid cracks

- Viewing Angle Variance: On‑Cell may exhibit more glare under angle stress

Häufig gestellte Fragen

Q1: Which technology offers the best optical performance?

In‑Cell and OGS both provide excellent transparency due to fewer internal reflections.

Q2: Which is most economical for mass production?

OGS generally offers the best cost-to-performance ratio.

Q3: Can these be used with gloves?

Yes, especially OGS and On‑Cell. In‑Cell may require tuning.

Q4: Can I replace just the touch layer if it breaks?

Only with OGS is partial repair feasible. In‑Cell and On‑Cell are fully bonded to the display.

Q5: Which is most suitable for rugged environments?

OGS with reinforced glass or cover lens is the most impact-tolerant.

Schlussfolgerung

Choosing between In‑Cell, On‑Cell, and OGS depends on your specific product needs:

- For ultra-thin and premium designs, go with In‑Cell

- For balanced integration and durability, use On‑Cell

- For cost-effective, scalable, and rugged devices, choose OGS

Each offers a unique combination of clarity, cost, manufacturability, and durability. Understanding these trade-offs ensures a better user experience and smoother product development.