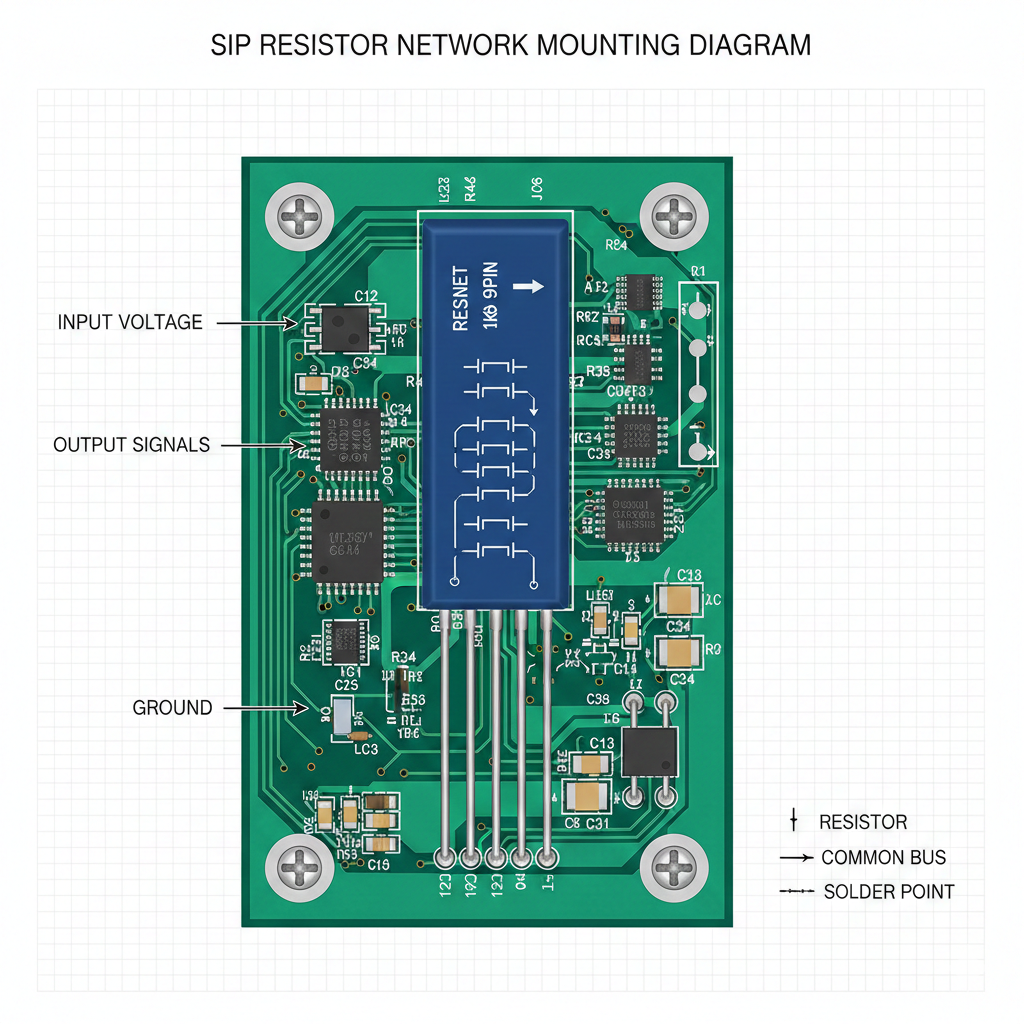

1. Defining the Single Inline Package: Structural Anatomy

A single inline package (SIP) is a component housing characterized by a single row of connecting pins (leads) protruding from its base. Unlike the Dual Inline Package (DIP) which uses two parallel rows, or the Quad Flat Package (QFP) which uses four sides, the SIP stands perpendicular to the board.

1.1 The Linear Logic

The pins of a single inline pin package are aligned in a precise, straight line.

- Standard Pitch: Most industrial SIPs utilize a 2.54mm (100 mil) pitch, ensuring compatibility with standard grid layouts and breadboards.

- Encapsulation: The internal circuitry is typically encased in a thermosetting epoxy or molded plastic. This protective shell is vital for Industrial-grade quality, shielding the silicon die or resistive film from oxidation, moisture, and dust.

1.2 SIP vs. Single Inline Pin Package

While the terms are often used interchangeably, a nuance exists in technical documentation. The “package” refers to the entire component, while the single inline pin package nomenclature emphasizes the mechanical interface. This linear pin configuration is what enables “vertical stacking”—the ability to line up multiple components like soldiers in a row, maximizing the use of the Z-axis.

2. Why “Vertical” Wins: The Competitive Advantages of SIP

When RJY architects a Systems & HMI solution, the choice of a single inline package is driven by specific environmental and spatial requirements.

2.1 Drastic PCB Footprint Reduction

The most immediate benefit of a single inline pin package is the conservation of X and Y board space. By standing the component upright, the footprint is reduced to a narrow rectangular strip. This allows designers to place passive arrays or power modules in the “gaps” between larger SMT chips, effectively increasing the component density per square inch without increasing the overall board size.

2.2 Superior Thermal Dynamics

Heat is the primary cause of component failure in high-performance IoT devices. Components that sit flush with the PCB often trap heat between their body and the substrate. In contrast, a single inline package is exposed to ambient air on both sides of its vertical body.

- Natural Convection: The vertical stance facilitates natural airflow, preventing the formation of stagnant “heat pockets.”

- Heatsink Integration: Many high-power SIPs (like the TO-220 style regulators) are designed with a metal tab for easy attachment to vertical heatsinks, which is essential for fanless Medical Equipment designs.

2.3 Modular Maintenance and Reworkability

In the industrial sector, downtime is expensive. Through-hole single inline package components are significantly easier to replace or upgrade than high-pin-count SMT devices. This modularity aligns with RJY’s commitment to Full-Cycle Innovation, ensuring that hardware can be maintained or iterated upon without requiring a total redesign of the carrier board.

3. High-Density Applications in Modern Industry

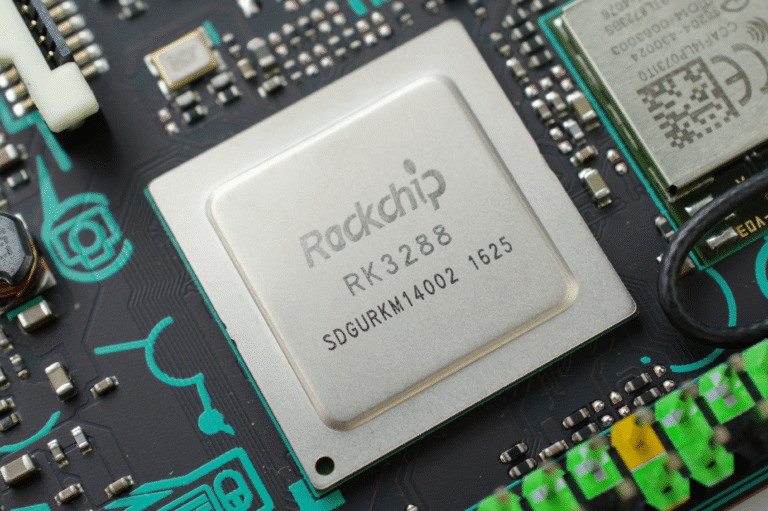

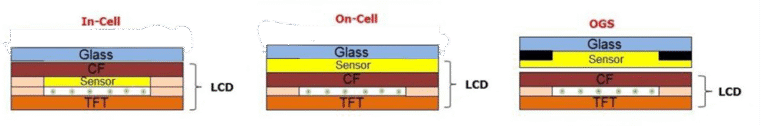

3.1 Bus Termination in Android 14 System Boards

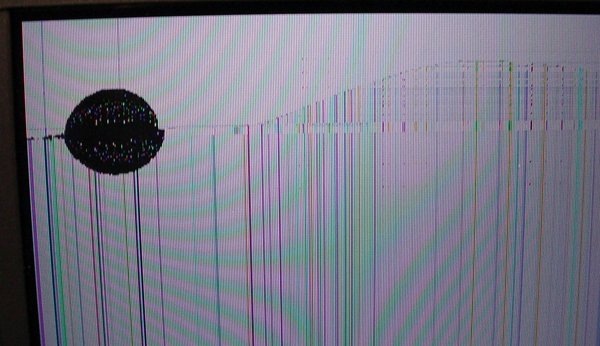

Modern high-speed buses require precise termination to prevent signal reflections. A single 10-pin single inline package resistor network can terminate nine signal lines simultaneously. This is a staple in RJY’s computing modules, ensuring that data traveling from a Rockchip processor to an lcd touch panel remains crisp and error-free.

3.2 Power Management for Industrial Robotics

Em Industrial Robotics, power rails must be clean and stable. SIP-based DC-DC converters are favored for their high power density and ability to handle the voltage spikes common in motor-driven environments. Their vertical orientation allows for the placement of bulk capacitors directly underneath the module, further optimizing the layout.

3.3 Analog Signal Isolation in Transportation

Para Transportation and EV charging infrastructure, isolation between high-voltage and low-voltage sections is a safety requirement. The physical height and single-row layout of the single inline pin package provide natural creepage and clearance distances, making it easier to meet stringent safety certifications.

4. Engineering Best Practices: Mounting and Reliability

To ensure Industrial-grade quality, designers must account for the mechanical leverage of a vertical component.

- Vibration Mitigation: In high-vibration environments, a tall single inline package can act as a lever, putting stress on the solder joints. RJY recommends using adhesive bonding at the base or choosing SIPs with “staggered” or “kinked” leads for better mechanical retention.

- Trace Routing Hygiene: Avoid running high-speed digital traces directly beneath a through-hole SIP to minimize parasitic capacitance and potential crosstalk between the pins and the board layers.

- Soldering Integrity: Achieving a 360-degree solder fillet is crucial. For automated lines, selective soldering is preferred over standard wave soldering to ensure consistent wetting for the single inline pin package leads.

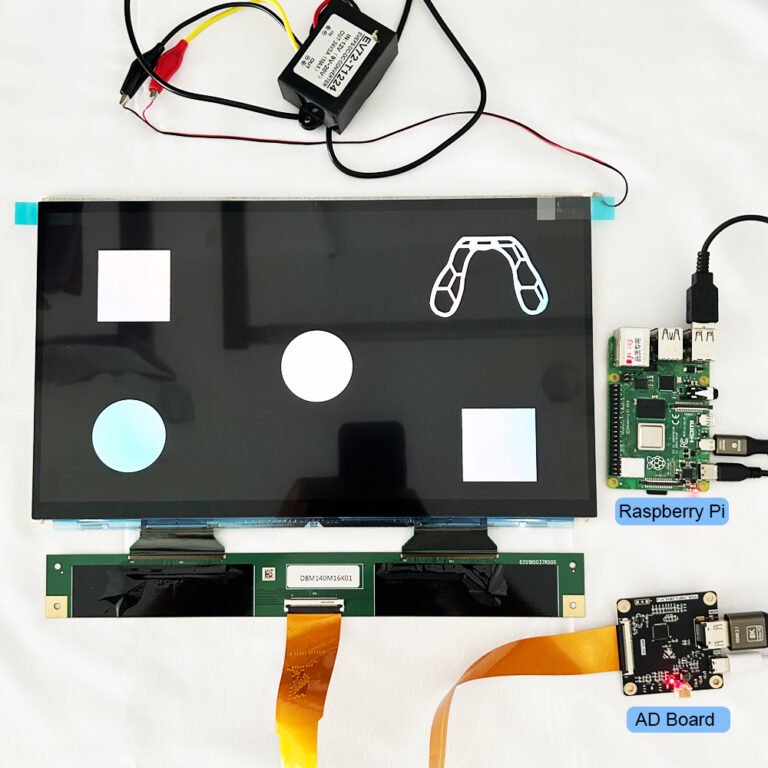

5. RJY’s Integration: The Bridge Between Compute and Display

As a full-cycle innovation hardware provider, RJY leverages the unique properties of the single inline package to deliver superior HMI systems.

- Shenzhen Agility: We utilize the rapid prototyping capabilities of the Shenzhen ecosystem to customize SIP headers and modules for niche industrial interfaces.

- Deep Customization: Our carrier boards often feature modular SIP interfaces, allowing clients to swap out communication modules (like RS-485 vs. CAN-bus) without changing the core Rockchip or NXP compute engine.

- System-Level Thinking: By integrating SIP components behind our lcd touch panel assemblies, we achieve a slim profile that doesn’t sacrifice the robustness required by the Smart Retail e Industrial IoT markets.

Conclusion: Vertical Thinking for a High-Tech Future

O single inline package is a testament to the fact that the most sophisticated solutions aren’t always the newest ones—they are the ones that solve spatial and thermal problems most efficiently. By embracing the vertical dimension, the SIP and single inline pin package provide the density, cooling, and modularity that define modern industrial hardware.

Em RJY, we integrate these robust packaging technologies with cutting-edge computing and display logic. From medical diagnostic tools to autonomous robots, our expertise in full-cycle innovation ensures that your hardware stands tall, regardless of the constraints.

Ready to maximize your board space and reliability?

Contact RJY Engineering today. Let us show you how our vertical integration strategies can accelerate your next high-performance HMI project.