- 1 What Defines an Industrial Touch Screen?

- 2 Core Components of an Industrial Touch Screen

- 3 Precision in Assembly: Where Performance Begins

- 4 Bonding Methods: OCA vs. OCR

- 5 Tausende von Produkten sind in unserem Katalog verfügbar.

- 6 Intelligent Circuit Design

- 7 Brightness and Backlight Control

- 8 Challenges of Rugged Housing Integration

- 9 Choosing the Right Touch Technology

- 10 Common Assembly Errors to Watch Out For

- 11 Compliance & Certification Standards

- 12 Reliability Testing Protocols

- 13 Customization for Industry Needs

- 14 Future Trends in Industrial Touch Screens

- 15 Final Thoughts

What Defines an Industrial Touch Screen?

At first glance, industrial touch screens may resemble commercial displays—but looks can be deceiving. These screens are purpose-built to operate in extreme environments filled with dust, moisture, vibration, oder temperature fluctuations.

Key features include:

- Long operating life under harsh conditions

- Reliable performance with gloves or water on the surface

- Resistance to EMI, ESD, and shock

- Seamless integration into customized enclosures or HMI systems

Imagine a smart terminal in a steel plant or a medical monitor inside a high-EMC lab. While both use the same basic principles, the build quality and tolerance differ significantly.

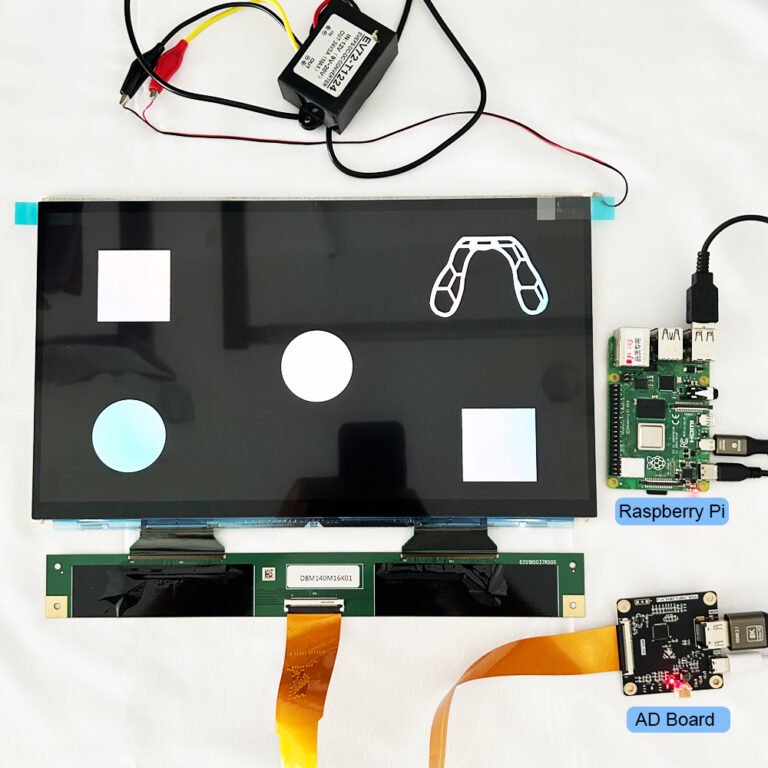

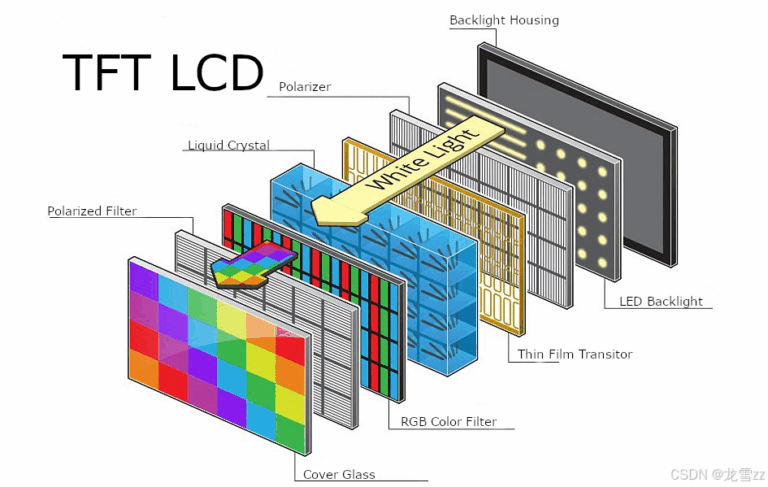

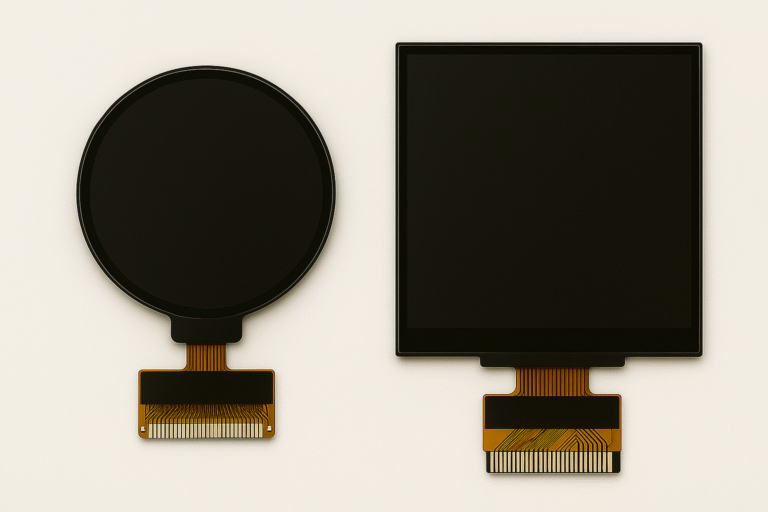

Core Components of an Industrial Touch Screen

The display starts with a TFT LCD panel, responsible for rendering images. Attached to it is a touch sensor, which is typically either projected capacitive (PCAP) for speed and gesture support, or widerstandsfähig for stylus and glove usage.

Together, they connect to a controller board that handles signal processing and communication with host devices. A durable LED backlight ensures brightness in varied lighting conditions, while the enclosure protects the system from mechanical stress and the elements.

Each component contributes to overall durability and user experience. A well-integrated system is more than the sum of its parts.

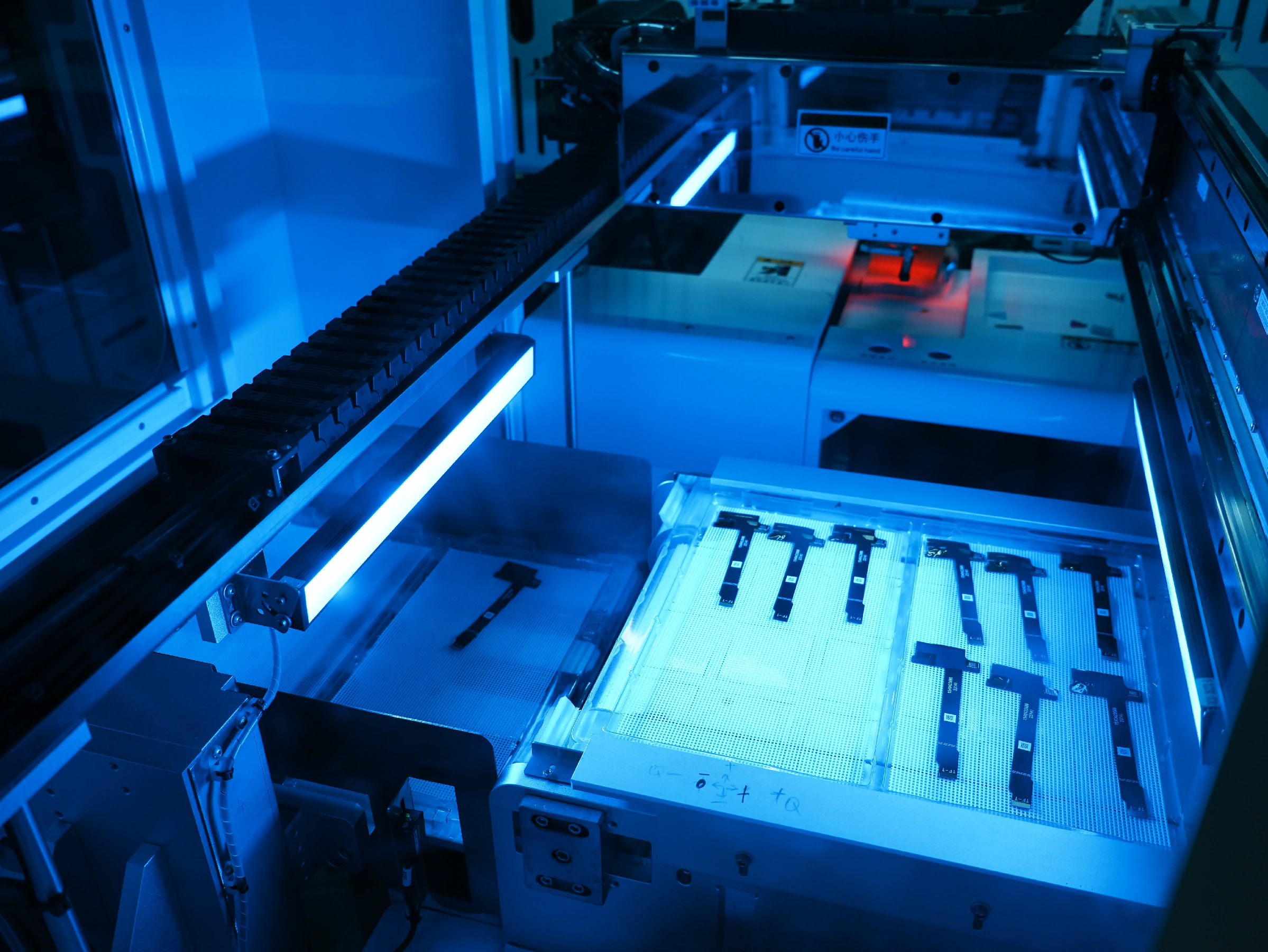

Precision in Assembly: Where Performance Begins

Industrial touch screen assembly takes place in static-free cleanroom environments. The bonding of the touch panel to the LCD must be performed with micron-level accuracy to ensure optical clarity and touch sensitivity.

Cabling and interfaces such as USB, I2C, oder UART must be firmly secured and properly shielded to prevent signal loss or interference. The connection architecture must also support extended lifecycle use, often exceeding 50,000 hours.

Mechanically, the screen is housed within metal enclosures—framed, sealed, or bolted—using anti-vibration gaskets, IP-rated sealsund CNC-milled mounts to ensure longevity.

Bonding Methods: OCA vs. OCR

Bonding technology is crucial for environments with sunlight, vibration, or contaminants. Removing the air gap between the touch panel and LCD reduces internal reflection and improves contrast.

Two main methods are:

- OCA (Optically Clear Adhesive): Solid film, quick to apply, ideal for mass production

- OCR (Optically Clear Resin): Liquid resin, better durability and clarity, ideal for outdoor or rugged use

Choosing the right bonding method depends on the screen size, use case, and environmental exposure.

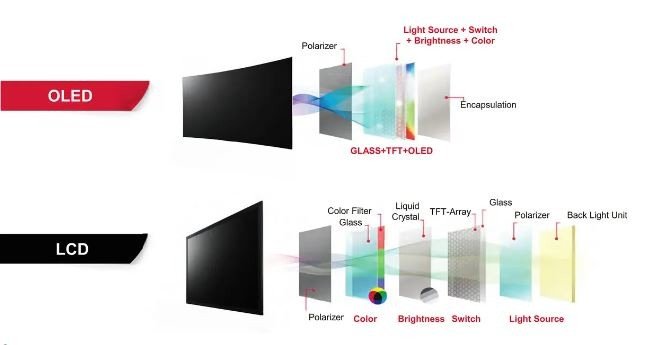

Tausende von Produkten sind in unserem Katalog verfügbar.

Entdecken Sie unsere breite Produktpalette, darunter LCD-TFTs, grafische und alphanumerische OLED-Displays, LCMs, E-Paper-Displays, Barcode-Scanner (eingebettet, handgehalten, fest montiert), Industriemonitore, Industriecomputer (Trägerplatinen, COMs & SOMs, eingebettete Systeme, HMI-Panel-Computer, SBCs), kapazitive und resistive Touchscreens sowie Zubehör (Entwicklungskits, Anschlüsse, Controller, FPC/FFC-Bänder, ZIF-Anschlüsse).

Intelligent Circuit Design

Industrial-grade controller boards are engineered for electrical resilience. Key features include:

- ESD and EMI protection circuits

- Wide voltage input support

- Watchdog timers for automatic recovery

- Secure grounding and signal isolation

These designs prevent malfunctions caused by power surges, noise, oder cable disconnects—common in industrial and medical settings.

Brightness and Backlight Control

In factories, warehouses, or outdoor locations, brightness consistency is critical. Industrial screens use high-brightness LED backlights, with some exceeding 1000 Nits.

Smart features may include:

- PWM-based dimming for ambient adaptation

- Temperature sensors for thermal throttling

- Diffusoren und Reflektoren to spread light evenly

These ensure long-lasting performance without overheating or brightness degradation.

Challenges of Rugged Housing Integration

Installing a screen into a rugged enclosure is far from trivial. It requires:

- IP65/IP67 waterproofing

- Vibration and impact resistance

- Compatibility with oil, chemicals, oder dust exposure

- Maintenance of a responsive touch layer despite sealing

Many manufacturers use hardened glass with anti-glare coatings, CNC aluminum framesund compression gaskets to deliver seamless functionality in tough environments.

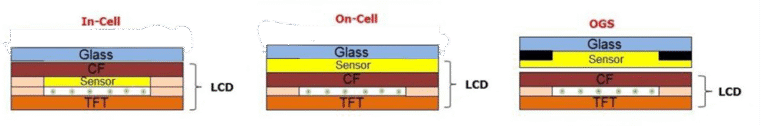

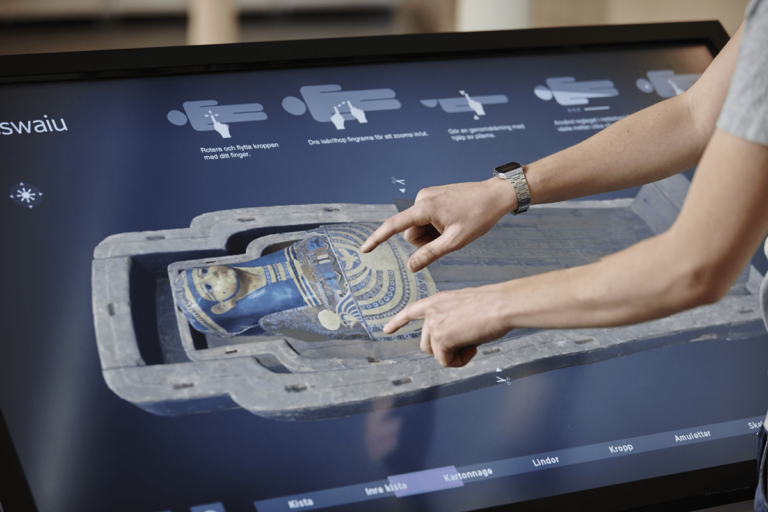

Choosing the Right Touch Technology

The application dictates the touch interface:

- Kapazitiv: Fast, sleek, multi-touch. Ideal for indoor use but needs tuning for water/gloves.

- Widerstandsfähig: Works with anything—fingers, gloves, tools—even in wet, dusty, or high-EMI conditions. Still widely used in military, mining, and outdoor control panels.

Common Assembly Errors to Watch Out For

No matter how good the components, poor assembly can ruin a product. Typical pitfalls include:

- Dust or bubbles in bonding

- Layer misalignment affecting calibration

- EMI-induced ghost touches

- Uneven brightness or backlight failure

Only thorough visual inspection, touch calibrationund burn-in testing can catch these before shipment.

Compliance & Certification Standards

Industrial customers demand reliability—and standards prove it. Look for compliance with:

- ISO9001 – Quality management

- CE/FCC – Electromagnetic compatibility

- RoHS – Environmental safety

- IP Ratings – Water/dust resistance

These certifications demonstrate consistent manufacturing and traceability.

Reliability Testing Protocols

Before hitting the field, industrial touch screens undergo:

- Thermal cycling (-30°C to 70°C)

- High-humidity stress tests

- EMC/EMI exposure assessments

- Shock and vibration simulations

Such tests ensure the screen performs under real-world abuse—not just lab conditions.

Customization for Industry Needs

One-size-fits-all rarely works in industrial design. Manufacturers often provide:

- Custom interfaces (USB, RS232, CAN)

- Firmware and OS driver adjustments

- Private-labeled front glass, bezels, or logos

- Custom brightness levels or touch tuning

Support for low-volume runs und just-in-time supply chains makes these screens viable across various sectors, from aerospace to agriculture.

Future Trends in Industrial Touch Screens

Looking ahead, we expect to see:

- Outdoor-friendly, ultra-bright displays

- Smart HMIs with voice/gesture integration

- Flexible and curved industrial panels

- Touch surfaces with embedded AI and diagnostics

Die industrial screen is rapidly becoming the intelligent interface of automated systems.

Final Thoughts

Die assembly of industrial touch screens is a critical process where engineering, precision, and environmental resistance converge. From the bonding layer to the PCB layout, every detail impacts reliability, clarity, and user experience.

For designers, integrators, and engineers alike—knowing what goes into a well-built touch screen is the first step to choosing the right one for your project.