- 1 Why Choose Real LCD Module Manufacturers Over Middlemen?

- 2 Common Types of TFT LCD Module Suppliers

- 3 Key Differences Between Factories and Trading Companies

- 4 How to Determine if TFT LCD Module Manufacturers Are Real Factories

- 5 Tausende von Produkten sind in unserem Katalog verfügbar.

- 6 How to Ask Strategic Questions During Inquiries

- 7 Identifiable Characteristics of Real Factories

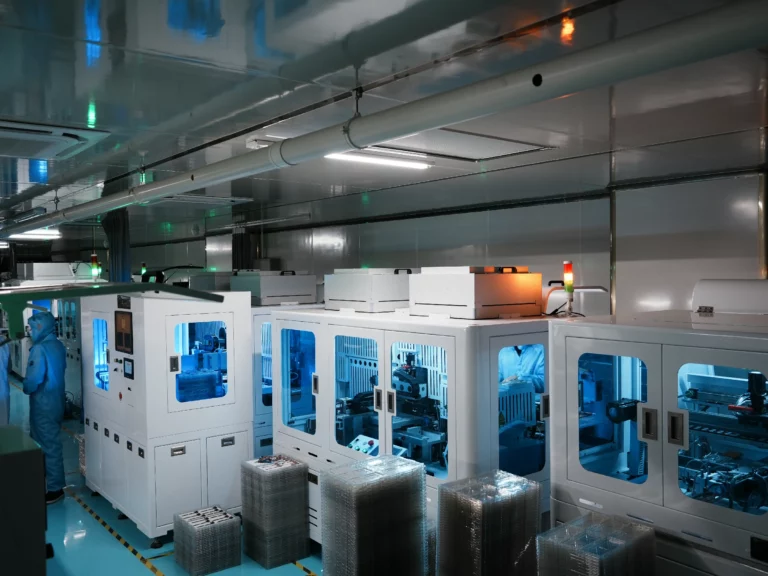

- 8 The Power of Video or On-site Factory Inspections

- 9 Technical Indicators to Evaluate a Factory’s Capabilities

- 10 Use Quotation Analysis to Spot Middlemen

- 11 Review Customer Cases and Collaborations

- 12 Real-World Example: How a Brand Identified a True LCD Manufacturer

- 13 Common Pitfalls and Scams to Avoid

- 14 Conclusion: Tips for Choosing Genuine TFT LCD Module Manufacturers

- 15 FAQs About LCD Factory Identification

Why Choose Real LCD Module Manufacturers Over Middlemen?

Partnering with a real LCD module factory provides clear advantages:

- Lower Costs: Direct factory pricing without layered markups.

- Better Quality Control: The factory handles the full production process, ensuring consistency.

- Faster Delivery Times: Direct control over scheduling and production.

- Flexible Anpassung: Factories often offer design, interface, and logo customization options.

Common Types of TFT LCD Module Suppliers

Before identifying the factory, it helps to understand the types of suppliers in the market:

- Original Manufacturer (Factory): Has its own production line, R&D team, and fixed production capacity.

- Brand Agent: Officially distributes a specific brand, with some stock and technical support.

- Trading Company: Sources from multiple factories, often lacks direct control over quality or timeline.

- Online Reseller: Found on platforms like AliExpress, 1688, or Amazon. Mostly trading companies.

Key Differences Between Factories and Trading Companies

| Aspekt | Factory | Middleman |

|---|---|---|

| Production Facility | ✅ Owns production lines | ❌ Typically does not manufacture |

| Technical Support | ✅ In-house engineers | ❌ Outsources or lacks expertise |

| Pricing Transparency | ✅ Cost-based and stable | ❌ Varies with high markup |

| Reaktionszeit | ✅ Fast and direct | ❌ Slower due to relay communication |

| After-Sales Service | ✅ Full accountability | ❌ Prone to blame-shifting |

How to Determine if TFT LCD Module Manufacturers Are Real Factories

Here are reliable methods for verification:

- Official Website: A legitimate manufacturer will have a corporate website with plant photos, workflow diagrams, and address information.

- Business Licenses and Certifications: Check if the business license includes terms like “manufacturer” or “production.”

- Third-party Platforms: Look for tags like “manufacturer” on sites like Alibaba or Made-in-China.

- Social Media Presence: LinkedIn, YouTube, or company WeChat accounts can reveal production capabilities.

Tausende von Produkten sind in unserem Katalog verfügbar.

Entdecken Sie unsere breite Produktpalette, darunter LCD-TFTs, grafische und alphanumerische OLED-Displays, LCMs, E-Paper-Displays, Barcode-Scanner (eingebettet, handgehalten, fest montiert), Industriemonitore, Industriecomputer (Trägerplatinen, COMs & SOMs, eingebettete Systeme, HMI-Panel-Computer, SBCs), kapazitive und resistive Touchscreens sowie Zubehör (Entwicklungskits, Anschlüsse, Controller, FPC/FFC-Bänder, ZIF-Anschlüsse).

How to Ask Strategic Questions During Inquiries

When contacting suppliers, use strategic questions to uncover their real identity:

- “How many production lines do you operate?”

- “Can you support factory inspections or video audits?”

- “Do you own COF bonding and automated assembly lines?”

- “Can you share your EMC or aging test equipment reports?”

A real factory will confidently answer, while a trading company might hesitate or provide vague responses.

Identifiable Characteristics of Real Factories

Look for these signs:

- Factory photos/videos showing operational assembly lines.

- Production workflow diagrams outlining each process step.

- Technical support team capable of sharing custom structure or FPC designs.

- Engineering team available for prototype customization and technical consulting.

The Power of Video or On-site Factory Inspections

When a long-term partnership or bulk order is involved, factory audits are essential:

- Verwenden Sie video calls to request a live walk-through of their production area.

- During on-site visits, evaluate equipment, warehouse management, and inspection protocols.

- Be cautious of staged environments—some fake factories rent locations just for appearances.

Technical Indicators to Evaluate a Factory’s Capabilities

A capable manufacturer will support:

- Various sizes/resolutions from 1.3” to 10.1” and beyond.

- High brightness and contrast TFT modules (e.g., 700+ nits).

- Multiple interface options like SPI, MCU, MIPI, HDMI.

- Custom structure and FPC design, with prototype turnaround time of 2–4 weeks.

Use Quotation Analysis to Spot Middlemen

Here’s how pricing can hint at authenticity:

- Real manufacturers offer transparent and tiered pricing based on quantity.

- They are more likely to provide custom quotes for bulk or unique requests.

- Trading companies often quote inconsistently, especially on technical projects.

Review Customer Cases and Collaborations

Genuine manufacturers often showcase:

- OEM/ODM partnerships with well-known end-user brands.

- Case studies or photos/videos of successful product integrations.

- Industry credentials or large-volume project references.

Real-World Example: How a Brand Identified a True LCD Manufacturer

A smart home brand started with 10 supplier inquiries:

- 5 were ruled out via technical questioning.

- 2 were exposed as “paper factories” during video audits.

- They selected a certified ISO manufacturer with verified R&D and 2M+ annual unit capacity.

Common Pitfalls and Scams to Avoid

- Too-good-to-be-true pricing usually signals poor quality or unreliable delivery.

- Fake certifications (e.g., Photoshopped ISO, RoHS documents).

- Staged factories—factories that exist only on camera or slides.

- Third-party outsourcing—they present as factories but outsource everything.

Conclusion: Tips for Choosing Genuine TFT LCD Module Manufacturers

In the TFT LCD industry, choosing the right supplier isn’t just about specs—it’s about trust. With careful research, smart questioning, and proper due diligence (like video audits and pricing logic), you can confidently identify TFT LCD module manufacturers that are truly capable and aligned with your business needs.

FAQs About LCD Factory Identification

- Can middlemen offer custom design services?

Some can, but they rely on factory partners and may have slow, inconsistent results. - How can I verify a supplier’s business license?

Use your country’s or China’s public business database (e.g., qcc.com or gsxt.gov.cn). - What if I can’t visit the factory in person?

Request a live video factory tour to evaluate equipment, production lines, and staff. - Are manufacturer tags on Alibaba reliable?

Look for “Verified Supplier” badges, but always verify via video or samples. - Why do samples from different suppliers vary so much in price?

Differences in quality, materials, and source (factory vs. trader) affect sample costs. - Can a real factory provide engineering documents?

Yes, real factories often share structure drawings or development outlines.