- 1 Understanding the Core of IPS Technology

- 2 OLED Displays: High Contrast, Low Tolerance

- 3 Key Performance Criteria in Industrial Display Applications

- 4 Burn-in and Long-Term Lifespan Management

- 5 Thermal and Environmental Robustness

- 6 Comparison Table: IPS vs OLED Displays at a Glance

- 7 Power Management and Real-World Efficiency

- 8 Supply Chain Stability and Manufacturing Flexibility

- 9 Display Selection Is a Strategic Engineering Decision

- 10 Final Thoughts: Build Your Display Strategy with RJY Display

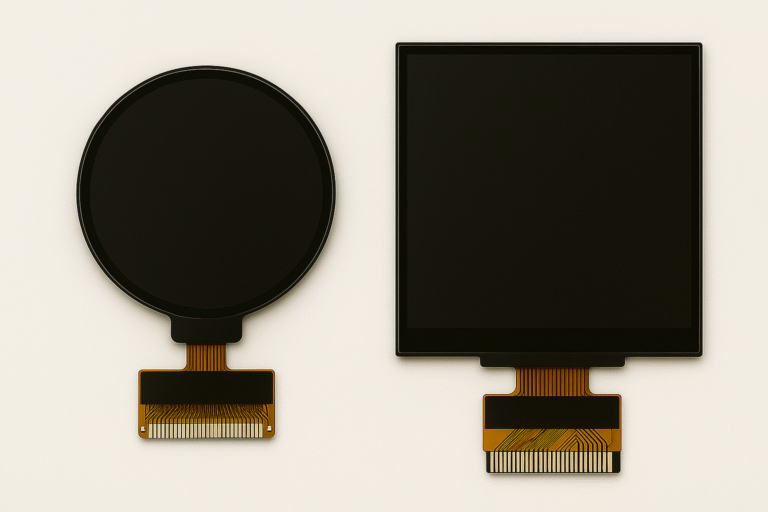

Understanding the Core of IPS Technology

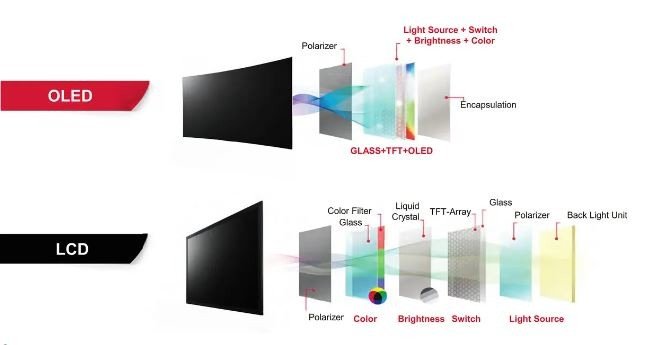

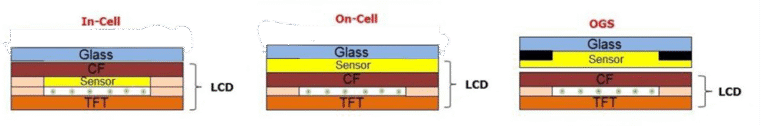

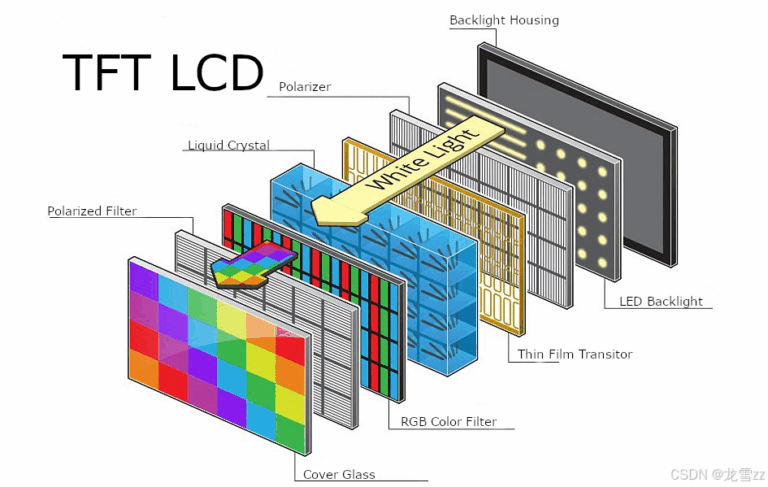

IPS (In-Plane Switching) is a refined LCD technology where liquid crystals are aligned parallel to the screen. This structure allows IPS panels to maintain superior color accuracy and consistency across a wide viewing angle, without the chromatic distortion common in older TN technologies.

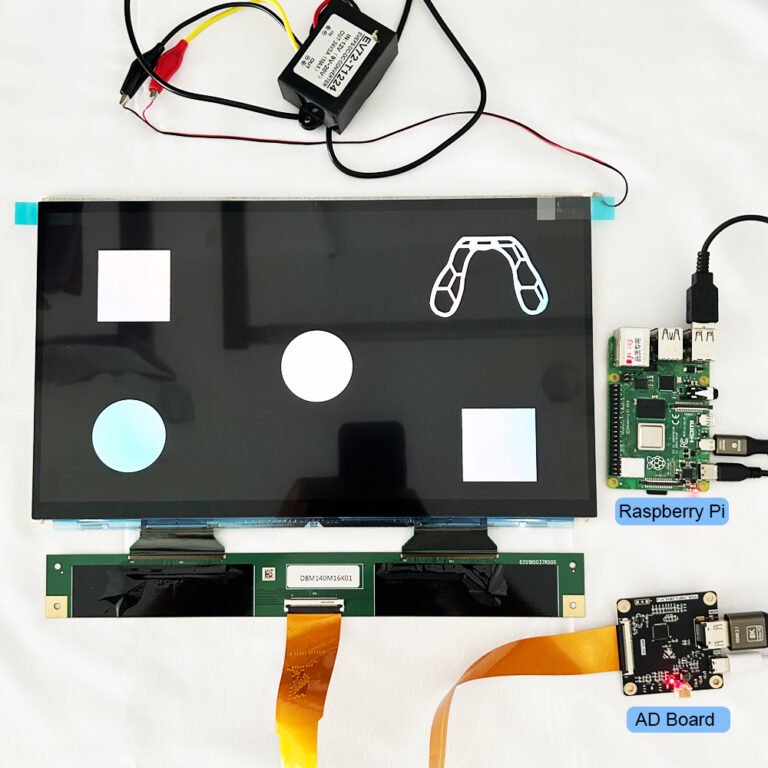

で RJYディスプレイ, we develop industrial-grade IPS modules designed for 24/7 performance, high luminance (over 1,000 nits), and optional optical bonding to reduce glare and increase mechanical durability. These characteristics are critical for factory HMIs, medical displays, and outdoor control terminals where stability and clarity are non-negotiable.

OLED Displays: High Contrast, Low Tolerance

OLED (Organic Light-Emitting Diode) displays work via self-emissive pixels, eliminating the need for a backlight. This architecture provides unparalleled contrast ratios, deeper blacks, thinner form factors, and faster response times — features that shine in premium consumer electronics or high-design user interfaces.

However, OLED panels are more susceptible to performance degradation, particularly in applications that involve static graphics, long durations of operation, or high-temperature environments. Burn-in and image retention are known issues, and material aging over time may compromise display uniformity. That’s why at RJY Display, we only recommend OLED for applications where aesthetics outweigh long-term performance metrics.

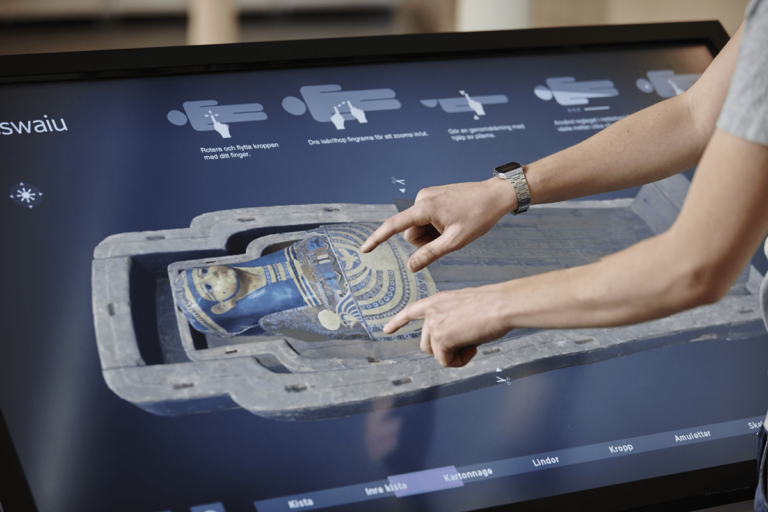

Key Performance Criteria in Industrial Display Applications

In real-world industrial deployments, theoretical specs don’t always hold. Displays must survive vibration, direct sunlight, electromagnetic interference, and a broad range of temperatures. IPS displays tend to outperform OLEDs in these conditions, delivering predictable luminance, stable color temperature, and long operational life.

At RJY Display, we integrate IPS modules into products used on manufacturing floors, medical diagnostic stations, agricultural vehicles, and beyond — all tested under thermal cycling, humidity stress, and long-term aging to ensure uncompromising reliability.

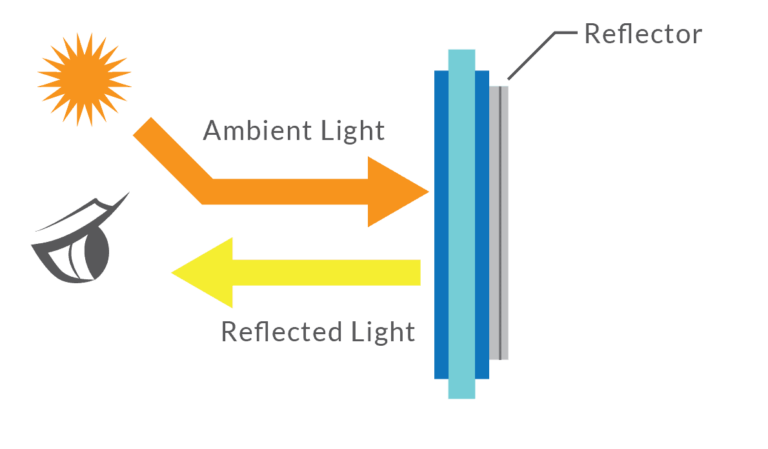

Burn-in and Long-Term Lifespan Management

One of the most critical distinctions in the IPS vs OLED displays debate is image retention. OLED panels suffer from pixel aging — especially when static UI elements are displayed over time — leading to irreversible burn-in. This is a major liability in 24/7 usage scenarios.

IPS displays, however, use a non-emissive LCD structure with external backlighting, which entirely avoids image retention and extends the service life of the display. With long-life LED backlights and precise temperature management, RJY Display ensures IPS modules maintain performance over 5 to 10 years of industrial deployment.

Thermal and Environmental Robustness

Industrial displays often face harsh operating environments — from subzero temperatures to high humidity or UV exposure. IPS panels generally have a higher tolerance for thermal expansion, vibration, and electrostatic discharge. This makes them ideal for applications requiring ruggedization and compliance with IP or military-grade standards.

OLEDs, on the other hand, are sensitive to both heat and humidity, and may degrade faster in such settings. Their thinner glass and organic layers often require reinforced encapsulation, which increases integration complexity and cost.

At RJY Display, we work with clients to test display modules in worst-case operating scenarios and design in optical coatings, UV protection, and rugged cover lenses to extend the functional lifespan of the display solution.

Comparison Table: IPS vs OLED Displays at a Glance

| Feature / Attribute | IPS Display (TFT LCD) | OLED Display |

|---|---|---|

| Light Emission | Requires backlight | Self-emissive (no backlight needed) |

| 視野角 | Excellent (up to 178°) | 素晴らしい |

| コントラスト比 | Moderate to High (typically ~1000:1) | Very High (>1,000,000:1) |

| 応答時間 | Moderate (~8–12 ms typical) | Very Fast (<1 ms typical) |

| Image Retention / Burn-in | No risk | High risk under static elements |

| Brightness in Sunlight | Strong with high-nit backlight | Limited (peak brightness not sustainable) |

| 消費電力 | Higher under full white, lower in high brightness | Lower at low brightness, varies by image |

| Lifetime | Long (50,000–70,000 hours backlight-based) | Shorter (typically 10,000–30,000 hours) |

| Environmental Tolerance | High (wide temp and humidity range) | Lower (sensitive to heat and moisture) |

| Cost & Availability | Lower cost, high manufacturing maturity | Higher cost, supply chain less stable |

Power Management and Real-World Efficiency

Power consumption is often misunderstood. While OLED can be more efficient when displaying black or low-brightness images, its overall energy consumption rises sharply with full-screen brightness — a scenario common in industrial UIs. Meanwhile, IPS backlighting can be optimized for zones, PWM dimming, and dynamic brightness adjustment.

RJY Display engineers customize LED backlights and driver circuits to suit each application’s real power budget. This includes adaptive dimming profiles, intelligent power-off control, and system-wide thermal balancing — all crucial for embedded designs with strict power and heat constraints.

Supply Chain Stability and Manufacturing Flexibility

The IPS TFT LCD industry benefits from decades of refinement, resulting in higher yields, scalable capacity, and better integration ecosystem. OLED manufacturing, in contrast, still faces yield challenges and volatility in material supply, which can result in extended lead times or batch inconsistencies.

With over 12,000 square meters of in-house production space in Shenzhen and advanced COG/FOG bonding, optical bonding, and full AOI testing, RJY Display ensures repeatability, quality, and cost control for both mass production and small-batch prototyping.

Display Selection Is a Strategic Engineering Decision

When evaluating IPS vs OLED displays, the conversation must go beyond specs. It’s about total system engineering — considering user environment, lifecycle requirements, integration constraints, compliance goals, and supply chain risk.

At RJY Display, we don’t just supply panels — we co-develop solutions. From early requirement definition through rapid prototyping and pilot production, we integrate optical, electrical, and mechanical engineering to ensure the display solution becomes a value-added component of your final product.

Final Thoughts: Build Your Display Strategy with RJY Display

Choosing between IPS and OLED isn’t about picking the “better” technology — it’s about choosing the right fit for your product’s purpose and longevity. OLED may be ideal for short-life, design-driven consumer applications. But for ruggedized, mission-critical, or compliance-sensitive products, IPS remains the display technology of record.

RJY Display supports both technologies, but our real strength lies in understanding your product goals and guiding you to the right long-term solution. If your project requires display customization, long-term supply support, and deep engineering collaboration, we invite you to partner with us.