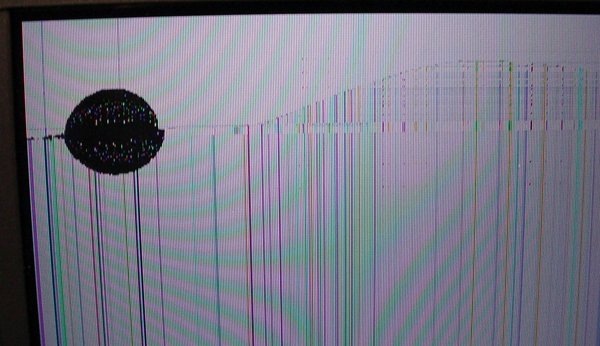

**Pixels morts ou bloqués : pourquoi vous voyez des points qui ne disparaissent pas**

L’un des problèmes d’affichage les plus reconnaissables est l’apparition de petits points statiques — noirs ou d’un rouge, vert ou bleu vif — qui ne réagissent pas aux changements à l’écran.

**Que se passe-t-il ?**

Il s’agit généralement **de pixels morts** (noirs et non fonctionnels) ou **de pixels bloqués** (fixés sur une seule couleur). Ils surviennent en raison de :

- Défaillances électriques minimes dans le circuit du pixel (défaut d’usine)

- Pression ou dommages physiques lors de la manipulation ou de l’utilisation

- Affichage prolongé d’images statiques provoquant une rémanence ou un gel du pixel

**Comment les réparer**

- Exécutez un logiciel de rafraîchissement de pixels qui alterne rapidement les couleurs — cela peut parfois “ relancer ” les pixels bloqués

- Affichez une vidéo à mouvement rapide ou des boucles de couleurs pendant plusieurs heures

- Si le pixel reste inchangé et que l’écran présente des marques de pression visibles, envisagez le remplacement du panneau

**Comment les prévenir**

- Évitez d’appuyer sur la surface de l’écran

- Utilisez un boîtier de protection ou des cadres dans les environnements difficiles

- Faites régulièrement tourner le contenu à l’écran pour éviter la rémanence d’image

**Écrans scintillants : quand l’affichage ne reste pas stable**

Le scintillement ou le clignotement rend difficile la lecture des données de processus ou l’interaction avec l’IHM. Ce problème est particulièrement fréquent sur les ateliers de production où la qualité de l’alimentation électrique peut fluctuer.

**Causes probables**

- Instabilité de l’alimentation (chutes ou pics de tension)

- Câbles défectueux ou blindage de mauvaise qualité

- Fréquence de rafraîchissement incompatible entre le moniteur et le système

- Pilotes d’affichage obsolètes ou incompatibles

**Mesures à prendre**

- **Vérifiez l’alimentation électrique**: Assurez-vous que votre moniteur est connecté à une source d’alimentation stable. L’utilisation d’un parasurtenseur peut aider à stabiliser la tension.

- **Inspectez les câbles**: Des câbles mal connectés ou de mauvaise qualité peuvent causer des problèmes. Les remplacer par des câbles blindés de haute qualité peut améliorer la situation.

- **Ajustez la fréquence de rafraîchissement**: Assurez-vous que la fréquence de rafraîchissement de votre moniteur correspond aux paramètres de votre système. Consultez le manuel de votre moniteur pour les réglages recommandés.

- **Mettez à jour les pilotes**: Maintenez vos pilotes graphiques à jour pour éviter les problèmes de compatibilité.

**Solution à long terme**

Mettez en place des routines de **maintenance préventive** incluant l’inspection des câbles, les mises à jour du micrologiciel et les vérifications environnementales des sources de CEM.

- L’utilisation de câbles de qualité et la garantie d’une alimentation stable peuvent minimiser le scintillement.

- Mettez régulièrement à jour les pilotes et effectuez des vérifications de maintenance générale pour éviter ces problèmes à l’avenir.

**Affichage flou ou basse résolution : quand le texte n’est pas net**

Lorsque vous essayez de lire des données importantes, l’écran apparaît flou ou pixelisé. Les images ou le texte peuvent ne pas être aussi nets qu’ils devraient l’être, même sans zoomer.

Si le texte ou les icônes semblent flous même à la taille normale, cela indique généralement une inadéquation entre la résolution native du panneau et la sortie du système.

**Causes possibles**

- L’affichage est réglé sur une **résolution non native**

- Désalignement interne dû à un **choc ou une vibration**

- Connexions desserrées dans le câblage interne ou les cartes de contrôle

**Solutions**

- Ajustez les paramètres pour correspondre à la résolution native de l’écran

- Fixez solidement les composants d’affichage dans les environnements à fortes vibrations

- Inspectez et repositionnez les câbles plats internes ou les broches des connecteurs

**Conseils de prévention**:

- Utilisez des moniteurs spécialement conçus pour résister aux vibrations ou aux chocs si vous travaillez dans des environnements où ceux-ci sont fréquents.

- Utilisez toujours la résolution native du moniteur pour maintenir la clarté de l’image.

**Bonnes pratiques**

Dans les installations industrielles avec des équipements lourds à proximité, utilisez des écrans certifiés pour la résistance aux chocs et aux vibrations, et montez-les avec des supports antivibrations.

Panne de rétroéclairage : Pourquoi mon écran devient-il sombre ?

Une perte soudaine de luminosité ou un écran noir indique souvent des problèmes de rétroéclairage— l’une des pannes les plus courantes sur les écrans vieillissants.

À quoi cela ressemble: L’écran devient soudainement très sombre ou complètement noir, rendant toute visibilité impossible. Cela se produit généralement lorsque le rétroéclairage de l’écran tombe en panne.

Déclencheurs principaux

- Dégradation des rétroéclairages CCFL ou LED due au vieillissement

- Panne de l’onduleur ou de la carte pilote

- Instabilité électrique affectant le circuit de rétroéclairage

Comment identifier

- Dirigez une lampe torche vers l’écran — si l’image est faible mais présente, le rétroéclairage est en cause

- Testez la tension de sortie du rétroéclairage ou remplacez la carte pilote

Corrections recommandées

- Remplacez les écrans CCFL par des modèles à rétroéclairage LED

- Remplacez les composants ou panneaux de rétroéclairage avec des taux de défaillance connus

- Évitez de fonctionner à une luminosité maximale sauf nécessité absolue

Écran tactile ne répondant pas : Quand les entrées ne sont pas enregistrées

Sur les terminaux IHM, des écrans tactiles non réactifs peuvent interrompre les opérations. Ceci est particulièrement critique lorsque les écrans servent d’ interface de contrôle principale.

À quoi cela ressemble: Vous appuyez sur l’écran, mais il ne répond pas, ou il réagit de manière erratique, enregistrant les touches de façon incorrecte ou aux mauvais endroits.

Causes courantes

- Dommages de surface (fissures, éclats, rayures)

- Capteur tactile défectueux ou dégradé

- Interférences environnementales (humidité, poussière, température)

Comment résoudre

- Nettoyez la surface avec un chiffon doux et non pelucheux imbibé d’alcool

- Recalibrez à l’aide des outils intégrés au système

- Pour les écrans résistifs, vérifiez le câblage ; pour les capacitifs, vérifiez la mise à la terre et la carte contrôleur

Prévention intelligente

- Utilisez des écrans tactiles industriels avec une protection IP

- Ajoutez des revêtements trempés antireflets

- Choisissez des panneaux capacitifs avec réglage pour gants dans les environnements extérieurs

Distorsion des couleurs : Quand l’écran paraît trop bleu, jaune ou délavé

La précision des couleurs est cruciale dans des applications comme le diagnostic médical ou ou la surveillance graphique de processus. Les décalages de couleur peuvent compromettre les performances ou même conduire à une interprétation erronée des données.

À quoi cela ressemble: Les couleurs à l’écran apparaissent déformées — soit trop vives, trop ternes, ou avec une teinte perceptible. Cela peut poser problème si une reproduction fidèle des couleurs est essentielle à votre travail.

Causes profondes

- Vieillissement des LED ou CCFL affectant l’équilibre des couleurs

- Paramètres non calibrés après des mises à jour du pilote

- Exposition aux UV ou chaleur extrême déformant les cristaux liquides

Comment diagnostiquer:

- Calibrez l’écran: Utilisez des outils d’étalonnage des couleurs pour garantir une reproduction correcte.

- Vérifiez les effets environnementaux: Assurez-vous que l’écran n’est pas exposé à des températures extrêmes ou à la lumière directe du soleil, ce qui peut fausser les couleurs.

- Inspectez le rétroéclairage: Vérifiez si le rétroéclairage fonctionne correctement, car ses défauts peuvent altérer la précision des couleurs.

Solutions

- Effectuez un étalonnage des couleurs à l’aide de profils ICC ou des outils intégrés

- Recherchez des problèmes d’uniformité ou d’usure des LED

- Éloignez l’écran de la lumière directe du soleil ou d’une chaleur excessive

Réflexions finales : Concevoir pour la durabilité dès le départ

De nombreux problèmes tels que Dommages ponctuels sur écran LCD ou un scintillement peuvent être attribués à des choix de conception — et pas seulement au vieillissement ou à des accidents.

Au RJY Display, nous aidons les fabricants d'équipements d'origine et les intégrateurs système à créer des écrans renforcés optimisés pour les environnements sévères. Des liaison optique et modules de rétroéclairage sur mesure à aux écrans tactiles compatibles avec le port de gants, nos solutions LCD personnalisées sont conçues pour résister aux réalités des déploiements industriels.

FAQ

Quelles sont les causes des dommages ponctuels sur les écrans LCD industriels ?

Les dommages ponctuels sur écran LCD résultent généralement de pixels bloqués ou morts, qui peuvent être causés par des défauts de fabrication, des images statiques prolongées ou une pression physique. Dans les environnements rigoureux, des vibrations excessives ou des chocs peuvent également endommager la couche de cristaux liquides.

Les pixels bloqués peuvent-ils être réparés ?

Dans certains cas, oui. L'exécution de logiciels de rafraîchissement de pixels ou l'affichage de motifs colorés à changement rapide peuvent parfois débloquer les pixels. Cependant, si la tache est causée par une défaillance matérielle, le remplacement du panneau peut être nécessaire.

Pourquoi mon écran industriel scintille-t-il par intermittence ?

Le scintillement est souvent lié à une instabilité électrique, des interférences de signal ou une incompatibilité entre la fréquence de rafraîchissement de votre appareil et la fréquence native du moniteur. Utiliser des câbles blindés de qualité et des sources d'alimentation stables résout généralement le problème.

Comment éviter les défaillances de l'écran tactile dans les environnements sévères ?

Utilisez des écrans tactiles classés IP65 ou supérieur, appliquez des films protecturs anti-reflets, et choisissez des écrans capacitifs adaptés aux saisies en portant des gants ou en milieu humide. Un étalonnage périodique garantit également une précision durable.

Que faire si mon écran s'assombrit soudainement ou devient noir ?

Cela indique probablement une défaillance du rétroéclairage. Vérifiez l'alimentation électrique et le circuit pilote des LED. Pour les modèles anciens avec rétroéclairage CCFL, envisagez de passer aux LED pour une meilleure longévité.

Puis-je réétalonner un écran tactile dont la réponse est inexacte ?

Oui. La plupart des systèmes industriels incluent un outil d'étalonnage ou une option de menu dédiée. L'étalonnage aligne la saisie tactile avec les coordonnées visuelles et doit être effectué régulièrement, surtout après l'installation ou des mises à jour du système.

Ressources de référence