- 1 Understanding LCD Technology

- 2 Common LCD Problems

- 3 Dead Pixels and Stuck Pixels

- 4 Backlight Bleeding and Uneven Brightness

- 5 Flickering Screens

- 6 Image Retention and Ghosting

- 7 Cracked or Damaged LCD Panels

- 8 Color Distortion

- 9 Touchscreen Malfunctions (For LCDs with Touch)

- 10 Diagnosing an LCD Problem

- 11 Preventive Measures Against LCD Problems

- 12 Industrial vs. Consumer LCD Problems

- 13 When to Repair vs. Replace

- 14 Future of LCD Technology and Problem Reduction

- 15 Conclusion

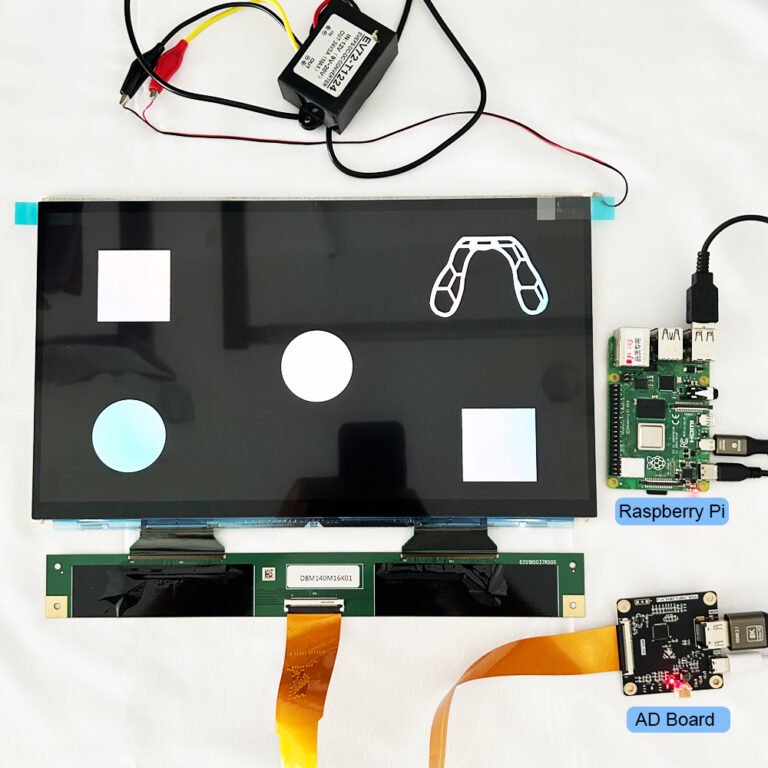

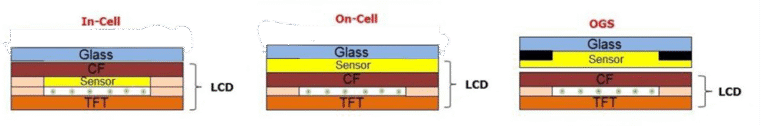

Understanding LCD Technology

An LCD functions by using liquid crystal material sandwiched between two glass layers, controlled by a backlight and thin-film transistors (TFT). When electrical signals are applied, the liquid crystals align to modulate light, creating images.

Key components include:

- Backlight: Provides illumination, usually LED-based.

- Polarizers: Control light direction.

- Liquid Crystals: Manipulate light passage to form pixels.

- TFT Array: Drives each pixel individually.

- Driver IC: Manages signal processing.

When an lcd problem arises, it is often linked to one or more of these critical elements.

Common LCD Problems

Dead Pixels and Stuck Pixels

- Symptoms: Small black dots (dead pixels) or brightly colored dots (stuck pixels).

- Causes: Defective sub-pixels or electrical misalignment.

- Solutions:

- Pixel-refresh or pixel-fixing software.

- Gentle pressure massage technique.

- In severe cases, screen replacement.

Backlight Bleeding and Uneven Brightness

- Symptoms: Light leaks around screen edges, especially visible in dark backgrounds.

- Causes: Imperfect panel assembly or uneven LED backlight distribution.

- Solutions:

- Adjust brightness levels.

- Use local dimming settings (if supported).

- Replace panel if bleeding is excessive.

Flickering Screens

- Symptoms: Noticeable flicker during refresh cycles.

- Causes: Faulty driver IC, unstable power supply, or low refresh rates.

- Solutions:

- Update display drivers or firmware.

- Check and stabilize power input.

- Replace faulty driver components.

Image Retention and Ghosting

- Symptoms: Previous images remain faintly visible even after the screen changes.

- Causes: Slow liquid crystal response or prolonged static images.

- Solutions:

- Use screen savers.

- Cycle content with moving images.

- Opt for higher refresh rate panels in critical applications.

Cracked or Damaged LCD Panels

- Symptoms: Visible cracks, black blotches, or distorted images.

- Causes: Physical shock, bending, or manufacturing defects.

- Solutions:

- Screen replacement is the only permanent fix.

- Protective cases and tempered glass can help prevent damage.

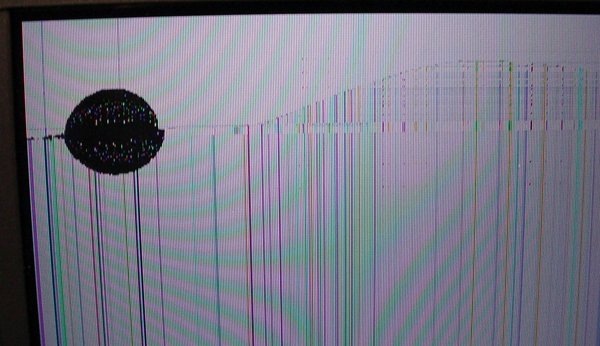

Color Distortion

- Symptoms: Images appear too warm, cold, or discolored.

- Causes: Misaligned liquid crystals, damaged polarizers, or GPU output issues.

- Solutions:

- Calibrate display using software tools.

- Check GPU/driver settings.

- Replace polarizer if hardware-related.

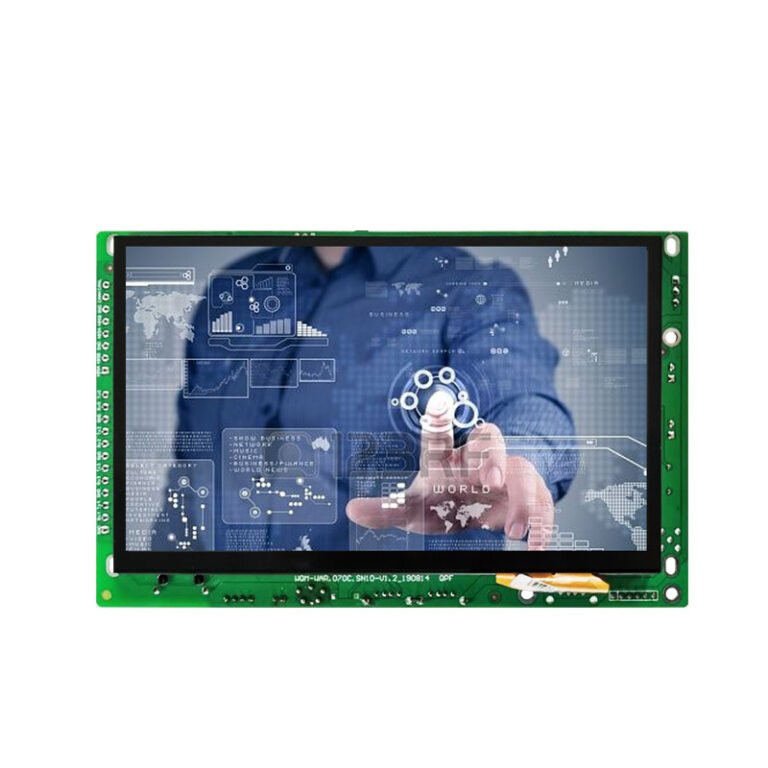

Touchscreen Malfunctions (For LCDs with Touch)

- Symptoms: Unresponsive or erratic touch input.

- Causes: Damaged touch digitizer, faulty connectors, or software bugs.

- Solutions:

- Recalibrate touchscreen.

- Reseat ribbon cables.

- Replace digitizer module if necessary.

Diagnosing an LCD Problem

Before repair, accurate diagnosis is critical. Engineers typically follow these steps:

- Visual Inspection – Look for cracks, discoloration, or leaks.

- Software Test – Use diagnostic apps to identify dead/stuck pixels.

- Hardware Test – Check power supply, cables, and connectors.

- Driver Check – Ensure latest drivers and firmware are installed.

- Component Isolation – Swap parts (cables, backlight drivers) to confirm the fault.

Preventive Measures Against LCD Problems

- Avoid prolonged static images to reduce burn-in.

- Keep devices within safe operating temperatures.

- Use screen protectors and cases to minimize physical damage.

- Perform regular calibration for accurate colors.

- Ensure stable power supply to prevent flickering and electrical stress.

Industrial vs. Consumer LCD Problems

| Category | Consumer Devices | Industrial Devices |

|---|---|---|

| Common Issues | Cracks, dead pixels, ghosting | Backlight aging, touch calibration drift |

| Environment | Indoor, mild use | Harsh conditions (dust, vibration, temperature extremes) |

| Durata della vita | 2–5 years | 7–10+ years with rugged design |

| Maintenance | Rarely repaired, often replaced | Regular calibration and preventive maintenance |

Industrial LCDs are generally designed with higher durability, advanced sealing (IP65/IP67), and longer lifespans compared to consumer-grade panels.

When to Repair vs. Replace

- Repair if: Problem is minor (stuck pixels, calibration, driver issues).

- Replace if: Screen is physically cracked, backlight is failing, or cost of repair approaches replacement cost.

For businesses relying on displays (factories, kiosks, medical equipment), replacing faulty LCDs quickly prevents downtime and operational inefficiency.

Future of LCD Technology and Problem Reduction

While OLED and MicroLED are emerging alternatives, LCD remains dominant due to cost-effectiveness and scalability. Manufacturers are addressing lcd problem challenges by:

- Using advanced backlight technology (Mini-LED for uniform brightness).

- Enhancing durata with stronger glass and coatings.

- Improving efficienza energetica to minimize flicker and heat.

- Extending product lifecycle support for industrial applications.

Conclusione

Un lcd problem can range from simple pixel defects to major hardware failures. By understanding the root causes—whether hardware, software, or environmental—users and engineers can apply effective solutions and preventive measures.

For consumers, this means maintaining device usability and extending lifespan. For businesses, it ensures operational continuity and cost efficiency.

While alternative display technologies are gaining traction, LCD remains a cornerstone of the global display market, and knowing how to troubleshoot and resolve LCD issues remains an essential skill.