1. TFT-LCDアレイ製造:基盤の構築

アレイ製造プロセスは、TFT-LCD生産における最初かつ最も重要な工程の一つです。液晶ディスプレイを制御する薄膜トランジスタアレイを作成する工程であり、成膜、エッチング、パターニングなどの複数のサブプロセスで構成されます。.

アレイ製造の主要工程:

- ガラス基板洗浄:プロセスは、最終的に表示パネルの基盤となるガラス基板の洗浄から始まります。ガラス表面に残留する不純物や残留物は、表示欠陥の原因となります。.

- 薄膜の成膜:ガラス基板上にシリコン(通常は非晶質シリコン)の薄膜が堆積されます。この層がTFTの基盤となります。続いて、液晶を制御する電極として、酸化インジウムスズ(ITO)などの導電層が形成されます。.

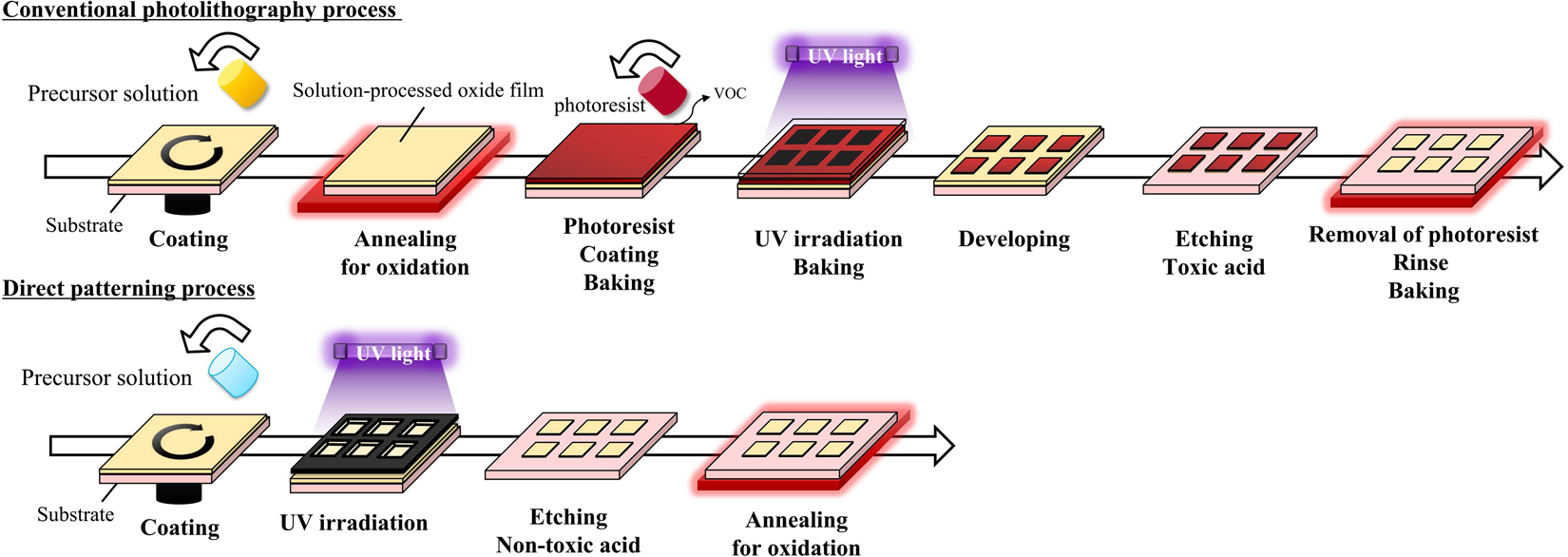

- フォトリソグラフィ:その後、基板上にTFTのパターンを定義するためにフォトリソグラフィプロセスが使用されます。光とマスクを用いて精密なパターンを基板に転写し、TFTアレイを形成します。この工程により、LCDの各画素に必要な制御点が確保されます。.

- エッチング:パターン転写後、基板はエッチング処理を受け、余分な材料を除去してTFTアレイの所望の構造のみを残します。.

2. セル製造:液晶セルの形成

アレイ製造後、TFT-LCD生産プロセスの次の工程は、個々の液晶セルの作成です。この工程では、2枚のガラス基板の間に液晶層を組み立て、両側に偏光フィルムを配置します。.

セル製造の主要工程:

- ガラス積層:TFTアレイを有する基板とカラーフィルターアレイを有する基板の2枚を積層します。2枚の基板は精密に位置合わせされ、適切な画素配置を確保します。.

- 液晶注入:基板の積層後、2枚のガラス層の間に液晶材料を注入します。使用される液晶材料の品質と種類は表示の視覚性能に直接影響するため、重要な工程です。.

- シーリング:液晶材料の漏れを防ぐため、ガラス基板の端部を封止します。シーリングプロセスは、2枚のガラス層間の必要な位置合わせを維持する役割も果たします。.

- 配向膜:ガラス内面に配向膜を形成し、液晶分子が最適な光変調のために正しい方向に配向されるようにします。.

3. モジュール製造:最終組み立て

TFT-LCD製造プロセスの最終工程はモジュール組み立てです。この段階では、バックライトユニット、タッチパネル、保護ガラス層などの追加部品を取り付け、完全な表示モジュールを形成します。.

モジュール製造の主要工程:

- バックライト組み立て:通常LEDで構成されるバックライトユニットを表示セルに取り付けます。LEDは表示に必要な照明を提供し、様々な照明条件下での視認性を確保します。バックライトは通常、光導波板(LGP)と組み合わせて画面全体に光を均一に分散させます。.

- タッチパネル統合:多くの最新TFT-LCDでは、タッチパネルが表示モジュールに統合されています。デバイスの要件に応じて、静電容量式または抵抗膜式のタッチパネルが適用されます。.

- 表面処理:最適な画質を確保するため、LCDパネル表面には防眩、防指紋、反射防止コーティングが施されることが一般的です。これらの処理は使用性を向上させ、表示装置の寿命を延ばします。.

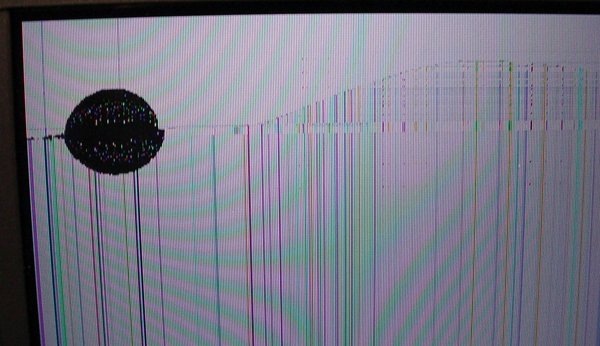

- モジュール封止とテスト:モジュール製造の最終工程では、内部部品を保護するため全体の組み立てを封止します。その後、表示装置の均一性、輝度、色精度についてテストが行われます。不具合が発見された場合、モジュールは追加検査または再調整を受けます。.

結論

TFT-LCD製造プロセスは、高度に専門的で精密な手順であり、複数の重要な工程を含みます。アレイ形成からセル製造、モジュール組み立てに至るまで、各段階は最終製品が現代の表示技術に期待される高水準を満たすために極めて重要な役割を果たします。様々な産業で先進的表示装置への需要が高まり続ける中、製造プロセスの革新はTFT-LCD生産の品質と効率をさらに向上させていくでしょう。.