Complete System Solutions for Innovative Projects

Are you looking for more than just computing or display solutions? Our engineering experts possess deep specialization in areas like computing, input/output (I/O), connectivity, chassis design, and motors, enabling us to design complete systems for Original Equipment Manufacturers (OEMs).

RJY provides system solutions for innovative businesses worldwide, including applications such as automatic cooking robots, sweeping robots, personal health and medical devices, and commercial and industrial automation equipment built upon existing modules. Leveraging the high-quality resources of Shenzhen, the “World’s Electronic Capital,” we are capable of rapid action—from prototyping, refining and optimizing product functions, to swiftly realizing mass production once the design is approved.

Full-Cycle Innovation

From Concept to Certified System Manufacturing.

RJY specializes in creating tailored solutions for various industries by integrating display, computing, and software technologies. From initial concept design through to deployment, we provide:

ODM HMI (Human-Machine Interface) and System Solutions

Custom Display and Custom Carrier Boards

Product Quality and Environmental Certifications

Custom Packaging and Logistics Network

Our process ensures seamless integration:

Conception > Hardware/Software Design > Validation/Certification > System Manufacturing

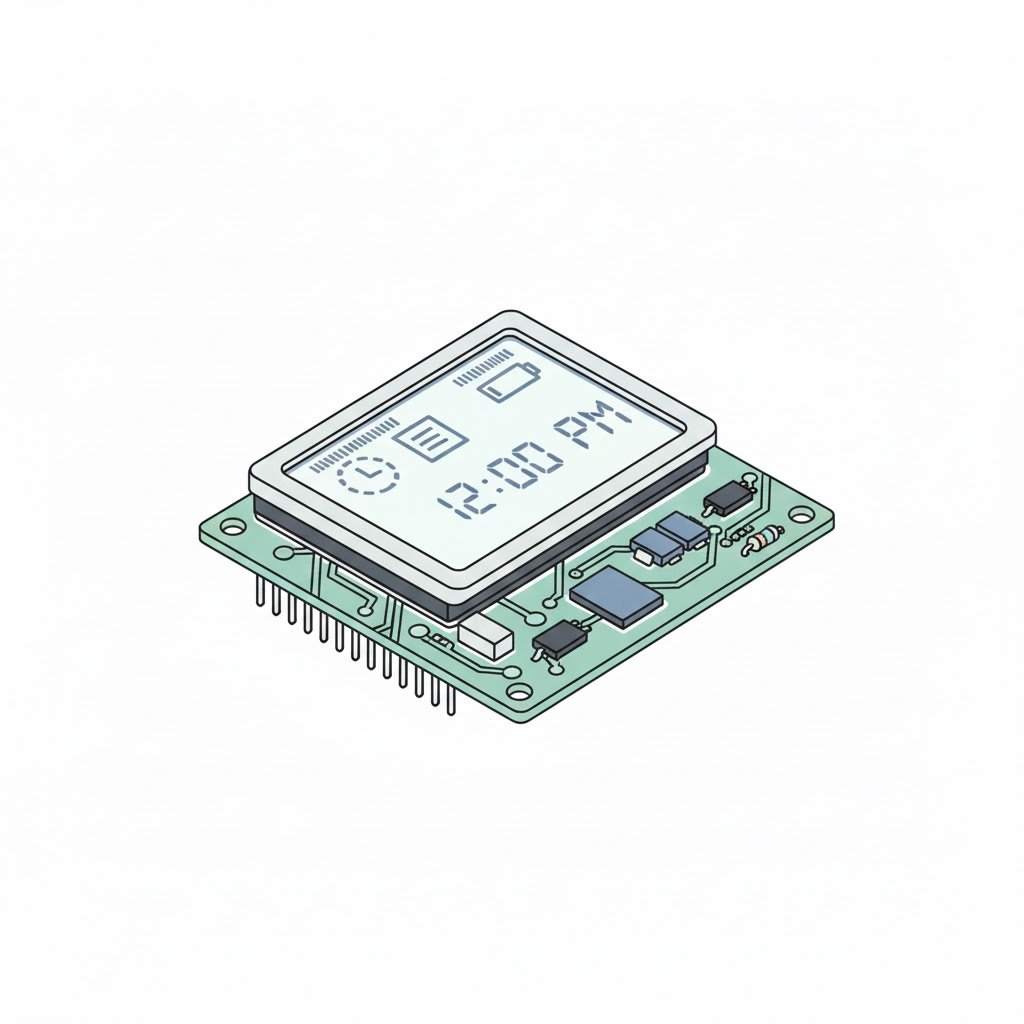

Display Modules

From standard specifications to unique custom shapes, we offer a full range of industrial-grade display module solutions. Combining advanced lamination technology with optical optimization, we create the most intuitive and reliable interactive interface for your equipment.

Systems & HMI

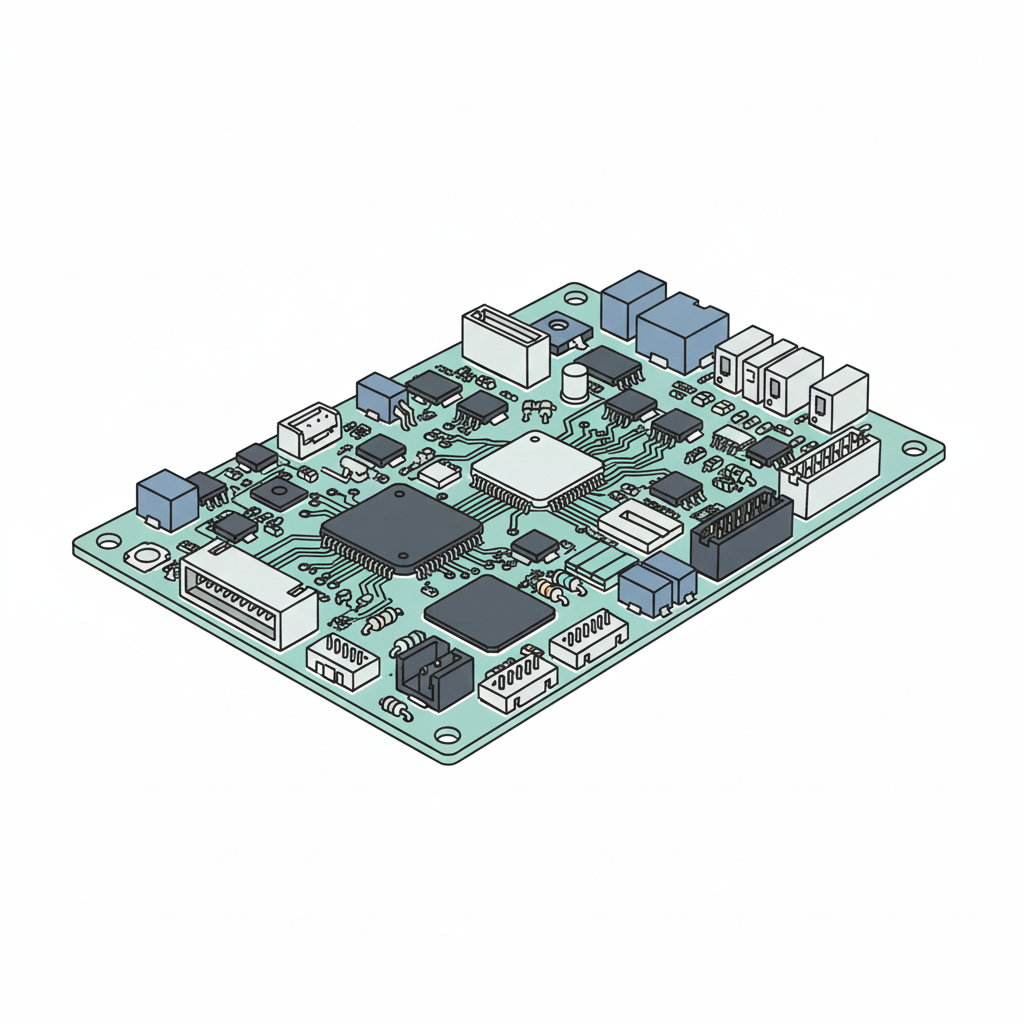

We provide full-stack solutions ranging from high-performance embedded motherboards to complete human-machine interface (HMI) systems, designed to simplify complex software and hardware integration and empower next-generation industrial and commercial equipment.

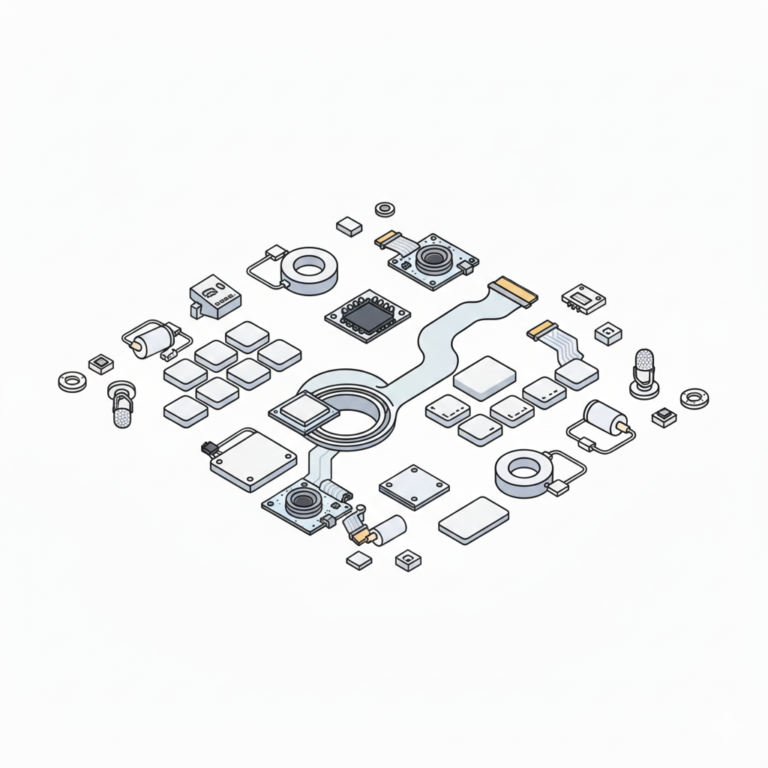

PCBA Customization

- Mainboard Design

- Contour Modification

- I/O

- Screen printing design

- Specific Design

Display Customization

- Custom Size & Resolution

- Backlight

- Aspect ratio

- Display interfaces

- FPC/Cable Optimization

- Optical Bonding

Touchscreen Customization

- Glass Size

- Capacitive or Resistive

- AG/AF/AR

- IC Matching

- Wet/Humid Environments

- Thickness

- Vandal-Proof Design

Casing Customization

- Size and shape

- Metal & Plastic

- Anti-Vibration Design

- Buttons & I/O Layout

- Silk-Screening

- Surface Finish

- Communication requirements

Component Customization

- Sensor Module

- Camera Module

- Connector

- Connector & Harness

- Power Management

- Specific Design

Software Customization

- Android/Linux System

- UI/UX Framework

- API and SDK Provision

- BSP Development

- Touch & Display Driver

Partnering with RJY: Collaboration Models

From Concept to Mass Production — Your Full-Cycle Hardware Partner

RJY teams believe that high-tech innovation requires more than just a supplier; it requires a strategic partner. Whether you are a global enterprise seeking high-grade quality or an innovator needing Deep Customization , we provide flexible collaboration models tailored to your project’s lifecycle.

Professional Customization

This solution focuses on deep customization. We design and manufacture bespoke systems tailored to your technical requirements.

- Hardware: Rockchip/NXP/Raspberry Pi/STM32 platforms, extensive I/O interfaces, and customizable plastic or metal enclosures.

- Display: Custom LCD touchscreens featuring AG/AF, specialized coatings (water droplet touch, glove touch), high brightness, and wide temperature range.

- Software: Android 14/Linux optimized adaptation, UI interface development, and driver integration.

- Pricing: One-time NRE (Non-Recurring Engineering) fee + unit price based on batch volume.

Standard Product & Modular Supply

Leverage our existing, field-tested Systems & HMI and Display Modules to reduce your Time-to-Market.

Speed: Utilizing our Shenzhen Agility, we maintain ready stock for most standard modules.

Low MOQ: We support small-batch orders for testing and evaluation kits.

Reliability: Benefit from our established industrial-grade supply chain.

- Pricing: Fixed unit price for samples and bulk production pricing.

Joint Innovation & Co-Development

We act as your extended engineering department, combining your industry expertise with our hardware integration mastery.

Support: Direct access to our FAE (Field Application Engineers) and software teams.

Agility: Fast iterations and rapid prototyping in the heart of Shenzhen.

IP Protection: Clear frameworks for intellectual property and joint innovation.

Individual & Small Project Support

RJY is committed to supporting every innovator. We lower the barrier to entry by offering:

Zero MOQ: No minimum order quantity for standard products.

Self-Service Resources: Access to online technical documentation and schematics.

Policy: To balance internal engineering costs, these projects are supplied without dedicated technical support or extended warranties.