Industry

Create new industrial equipment with RJY

In the era of Industry 4.0 and smart manufacturing, the Human-Machine Interface (HMI) is the critical link connecting operators, data, and machines. RJY Display focuses on providing powerful, integrated hardware and software display solutions for the demanding environments of industrial control and automation.

Leveraging over a decade of embedded development experience, we are dedicated to overcoming the unique challenges inherent in industrial applications. We commit to offering long life-cycle support, wide operating temperature ranges, and exceptional stability and reliability, helping you simplify product maintenance and significantly reduce your Total Cost of Ownership (TCO).

RJY supports industrial equipment OEMs with:

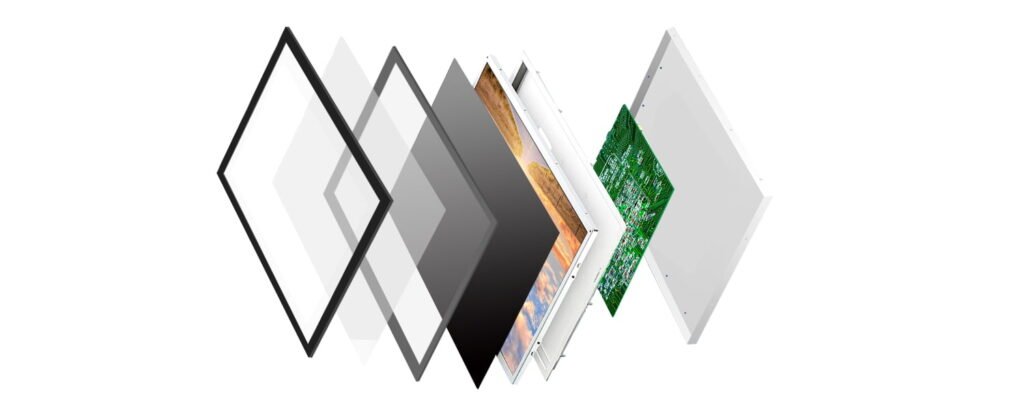

Display Modules:

7~15.6-inch industrial-grade display modules. Features high brightness, Anti-Glare (AG) / Anti-Fingerprint (AF) cover glass, and wide operating temperature design.

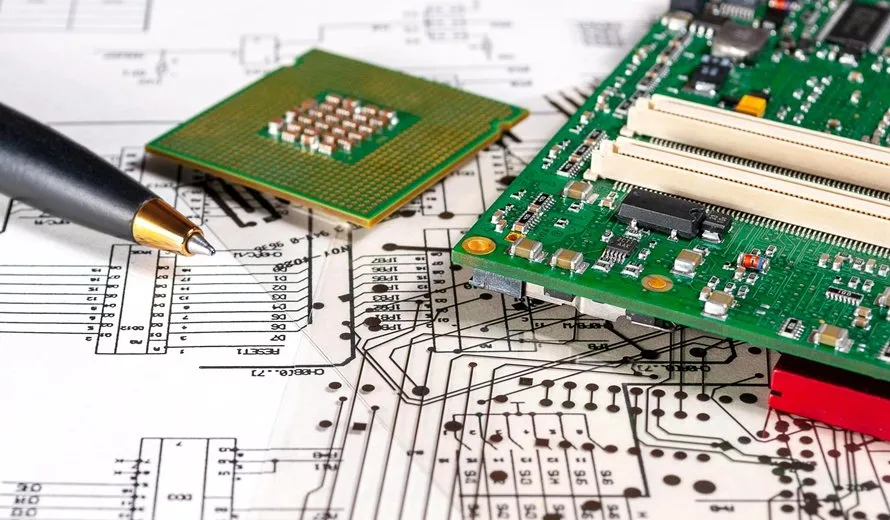

Computing Modules:

Multi-core Rockchip high-performance mainboards, compatible with mainstream systems such as Android, Linux, and Ubuntu, with rich interfaces to meet the needs of industrial computing.

Enclosure Design:

Customized metal or plastic materials, button adaptation, internal thermal management, structural integrity, interface layout, and brand silk-screening.

Explore our range of industrial-focused technologies

RJY offers a portfolio of standard computing modules and display kits perfectly suited for various industrial application scenarios. All modules support full customization and are also compatible with product series from different brand manufacturers.

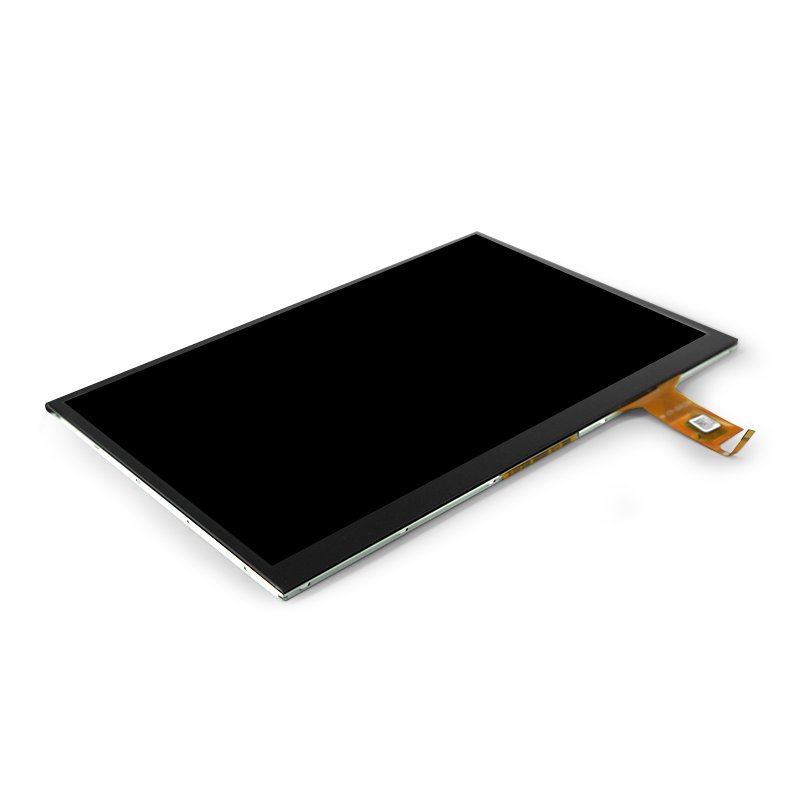

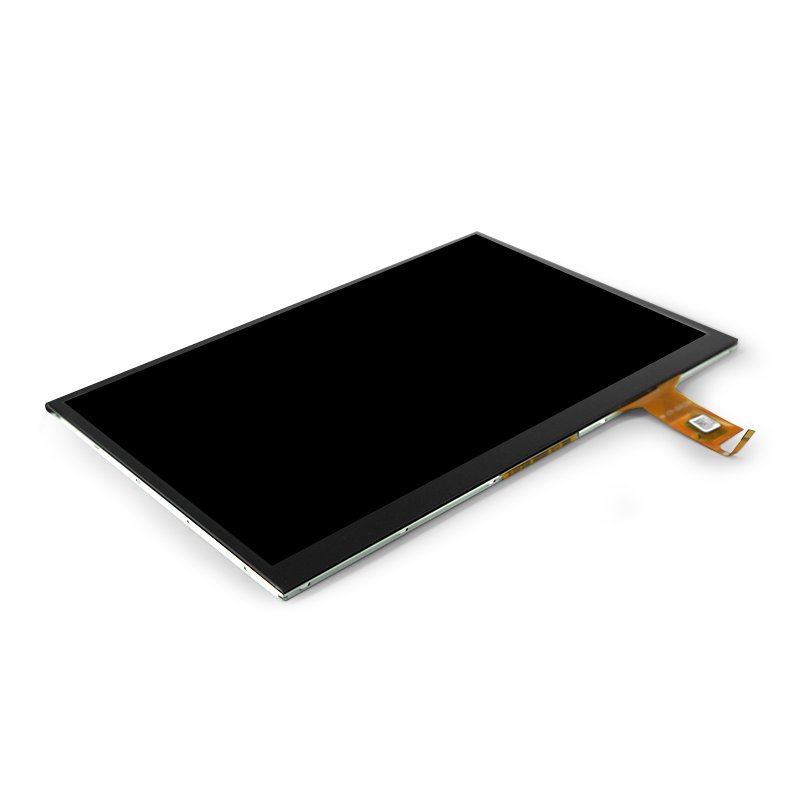

Display Modules

RV0101...

The RV101 is engineered for industrial touch applications, featuring BOE glass and an Anti-Glare (AG) cover glass, with support for multi-touch and glove operation.

This display module combines high brightness, high resolution, and excellent wide-temperature design. It can be utilized as a standalone display unit or integrated seamlessly into larger, customized systems.

RV0101...

The RV101 is engineered for industrial touch applications, featuring BOE glass and an Anti-Glare (AG) cover glass, with support for multi-touch and glove operation.

This display module combines high brightness, high resolution, and excellent wide-temperature design. It can be utilized as a standalone display unit or integrated seamlessly into larger, customized systems.

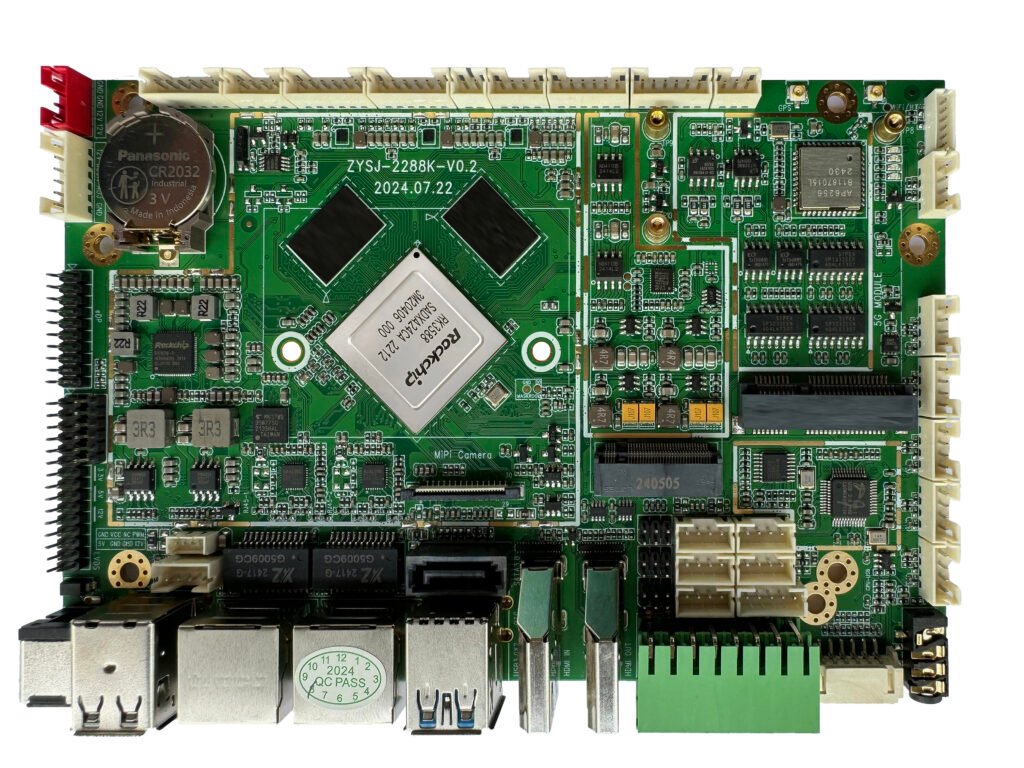

Computing Modules

RJY - 2288K

The RV101 is engineered for industrial touch applications, featuring BOE glass and an Anti-Glare (AG) cover glass, with support for multi-touch and glove operation.

This display module combines high brightness, high resolution, and excellent wide-temperature design. It can be utilized as a standalone display unit or integrated seamlessly into larger, customized systems.

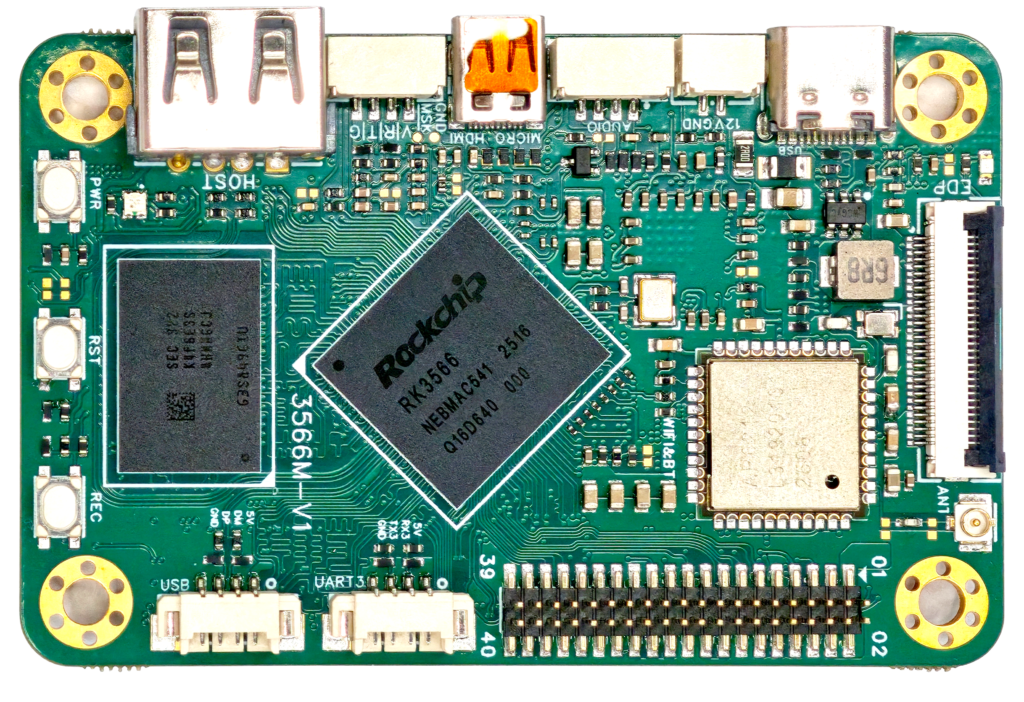

RJY - 3566M

The RV101 is engineered for industrial touch applications, featuring BOE glass and an Anti-Glare (AG) cover glass, with support for multi-touch and glove operation.

This display module combines high brightness, high resolution, and excellent wide-temperature design. It can be utilized as a standalone display unit or integrated seamlessly into larger, customized systems.

Explore our industrial-grade module ranges

Customization

Leveraging our in-house design and robust supply chain capabilities, RJY can customize your display and embedded computing requirements to precisely fit your specific operational environment and application.

Display customization options include:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Display customization options include:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.