- 1 Dead or Stuck Pixels: Why You See Dots That Don’t Disappear

- 2 What’s Happening?

- 3 How to Fix It

- 4 How to Prevent It

- 5 Flickering Screens: When the Display Won’t Stay Still

- 6 Likely Causes

- 7 What You Can Do

- 8 Long-Term Fix

- 9 Blurry or Low-Resolution Display: When Text Isn’t Clear

- 10 What Causes It

- 11 Solutions

- 12 Prevention Tips:

- 13 Best Practices

- 14 Backlight Failure: Why Is My Screen Going Dim?

- 15 Key Triggers

- 16 How to Identify

- 17 Recommended Fixes

- 18 Touchscreen Not Responding: When Input Goes Unregistered

- 19 Common Causes

- 20 How to Resolve

- 21 Smart Prevention

- 22 Color Distortion: When the Display Looks Too Blue, Yellow, or Washed Out

- 23 Root Causes

- 24 Fixes

- 25 Final Thoughts: Building for Durability from the Start

- 26 FAQ

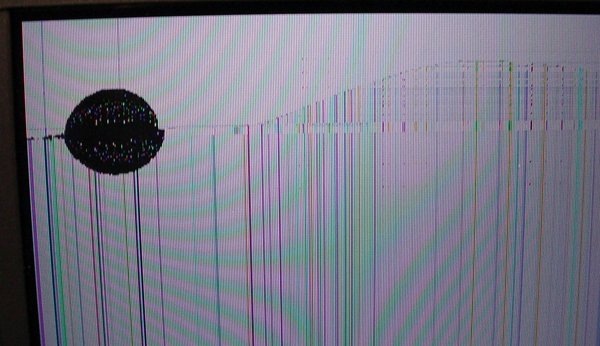

Dead or Stuck Pixels: Why You See Dots That Don’t Disappear

One of the most recognizable display issues is the appearance of small, static dots—black or bright red, green, or blue—that don’t respond to changes on the screen.

What’s Happening?

These are typically dead pixels (black and non-functional) or stuck pixels (fixed on a single color). They occur due to:

- Tiny electrical failures in the pixel circuit (factory defect)

- Pressure or physical damage during handling or operation

- Long-term display of static images causing pixel burn-in or freeze

How to Fix It

- Run pixel refresh software that cycles colors rapidly—sometimes this “shocks” stuck pixels back to life

- Display fast-moving video or color loops for several hours

- If the pixel remains unchanged and the screen has visible pressure marks, consider panel replacement

How to Prevent It

- Avoid pressing on the display surface

- Use protective casing or bezels in rugged environments

- Rotate content on-screen regularly to prevent image retention

Flickering Screens: When the Display Won’t Stay Still

Flickering or blinking makes it difficult to read process data or interact with the HMI. This issue is especially common in factory floors where power supply quality may fluctuate.

Likely Causes

- Power instability (voltage drops or spikes)

- Faulty cables or poor-quality shielding

- Mismatched refresh rates between the monitor and system

- Outdated or incompatible display drivers

What You Can Do

- Check the Power Supply: Ensure that your monitor is connected to a stable power source. Using a surge protector can help stabilize the voltage.

- Inspect Cables: Loose or poor-quality cables can cause issues. Replacing them with high-quality, shielded cables can improve the situation.

- Adjust Refresh Rate: Make sure the refresh rate of your monitor matches your system’s settings. Check your monitor’s manual for the recommended settings.

- Update Drivers: Keep your graphics drivers up to date to avoid compatibility issues.

Long-Term Fix

Implement preventive maintenance routines that include cable inspection, firmware updates, and environmental checks for EMI sources.

- Using good-quality cables and ensuring a stable power supply can minimize flickering.

- Regularly update drivers and perform general maintenance checks to avoid these issues in the future.

Blurry or Low-Resolution Display: When Text Isn’t Clear

When you’re trying to read important data, the screen looks blurry or pixelated. Images or text might not be as sharp as they should be, even when you’re not zooming in or out.

If text or icons look fuzzy even when zoomed to normal size, this usually signals a mismatch between the panel’s native resolution and the system’s output.

What Causes It

- Display is set to non-native resolution

- Internal misalignment from shock or vibration

- Loose connections in internal wiring or controller boards

Solutions

- Adjust settings to match the display’s native resolution

- Secure display components in high-vibration environments

- Inspect and re-seat internal flat cables or connector pins

Prevention Tips:

- Use monitors specifically designed to handle vibrations or shocks if working in environments where these are prevalent.

- Always use the monitor’s native resolution to maintain image clarity.

Best Practices

In industrial setups with heavy equipment nearby, use displays certified for shock and vibration resistance, and mount them with anti-vibration brackets.

Backlight Failure: Why Is My Screen Going Dim?

A sudden loss of brightness or a black screen often points to backlight issues—one of the more common failures in aging displays.

What It Looks Like: The screen suddenly becomes very dim or goes completely black, making it impossible to see anything. This usually happens when the backlight of the display fails.

Key Triggers

- CCFL or LED backlight degradation due to age

- Inverter or driver board failure

- Power instability affecting the backlight circuit

How to Identify

- Hold a flashlight to the screen—if the image is faint but present, the backlight is the issue

- Test backlight voltage output or replace the driver board

Recommended Fixes

- Upgrade CCFL displays to LED backlight models

- Replace backlight components or panels with known failure rates

- Avoid running at 100% brightness unless absolutely necessary

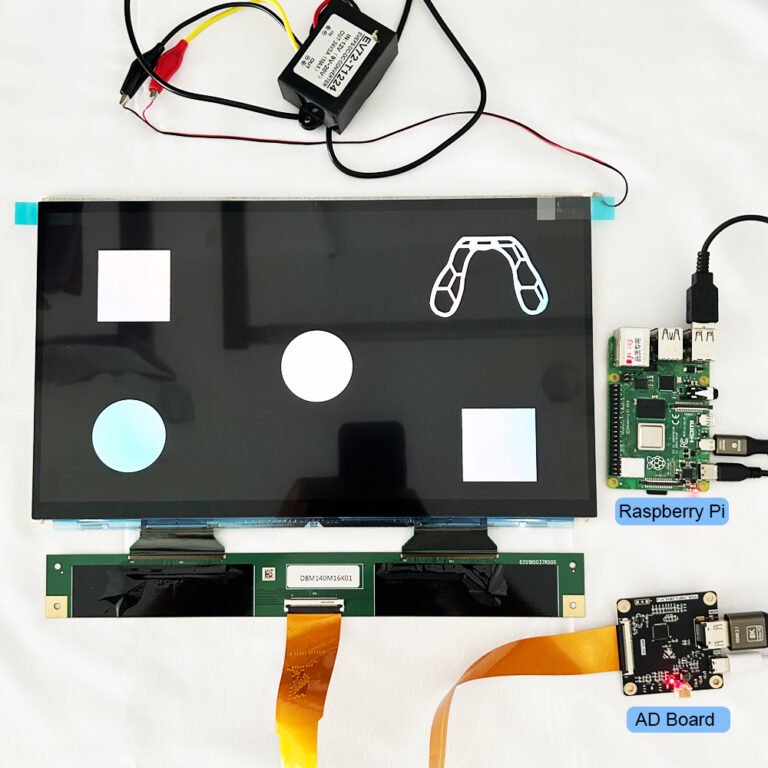

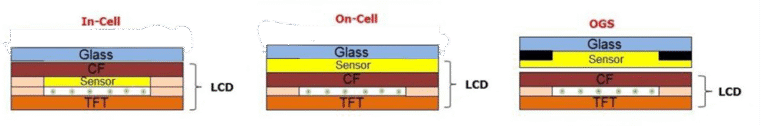

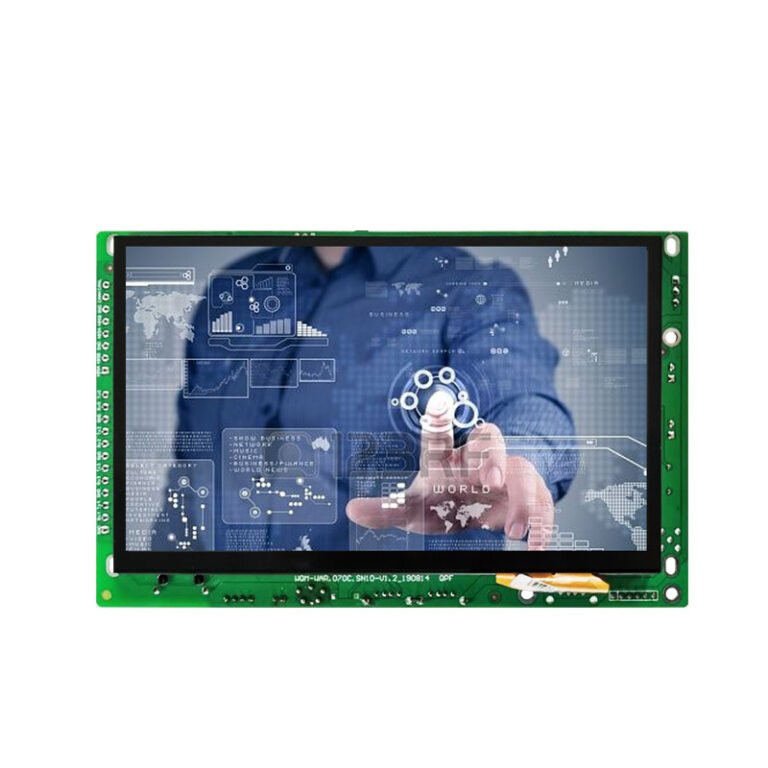

Touchscreen Not Responding: When Input Goes Unregistered

In HMI terminals, unresponsive touchscreens can halt operations. This is especially critical when screens serve as the main control interface.

What It Looks Like: You tap the screen, but it doesn’t respond, or it behaves erratically, registering touches incorrectly or in the wrong locations.

Common Causes

- Surface damage (cracks, chips, scratches)

- Faulty or degraded touch sensor

- Environmental interference (moisture, dust, temperature)

How to Resolve

- Clean the surface with a soft, lint-free cloth and alcohol

- Recalibrate using the system’s built-in tools

- For resistive screens, check wiring; for capacitive, check grounding and controller board

Smart Prevention

- Use industrial touchscreens with IP-rated protection

- Add anti-glare tempered overlays

- Choose capacitive panels with glove support tuning for field use

Color Distortion: When the Display Looks Too Blue, Yellow, or Washed Out

Color accuracy is critical in applications like medical diagnostics または graphical process monitoring. Color shifts can compromise performance or even lead to incorrect data interpretation.

What It Looks Like: The colors on your screen appear distorted—either too bright, too dull, or with a noticeable tint. This can cause problems if accurate color display is important for your work.

Root Causes

- Aging LEDs or CCFLs affecting color balance

- Uncalibrated settings after driver updates

- UV exposure or extreme heat deforming the liquid crystals

How to Troubleshoot:

- Calibrate the Screen: Use color calibration tools to ensure the display is showing colors correctly.

- Check for Environmental Effects: Ensure the screen isn’t exposed to extreme temperatures or sunlight, which can distort colors.

- Inspect the Backlight: Check if the backlight is functioning properly, as issues here can lead to poor color accuracy.

Fixes

- Perform color calibration using ICC profiles or onboard tools

- Inspect for uniformity issues or LED wear

- Move the display away from sunlight or excessive heat

Final Thoughts: Building for Durability from the Start

Many issues like LCD spot damage or flickering can be traced back to design decisions—not just aging or accidents.

で RJYディスプレイ, we help OEMs and system integrators create ruggedized displays optimized for harsh environments. From 光結合 そして custom backlight modules へ glove-compatible touch panels, our custom LCD solutions are built to withstand the realities of industrial deployment.

よくあるご質問

What causes LCD spot damage in industrial screens?

LCD spot damage usually results from stuck or dead pixels, which may be caused by manufacturing defects, prolonged static images, or physical pressure. In rugged environments, excessive vibration or impact can also damage the liquid crystal layer.

Can stuck pixels be repaired?

In some cases, yes. Running pixel-refresh software or displaying fast-changing color patterns can sometimes unstick pixels. However, if the spot is caused by hardware failure, panel replacement may be necessary.

Why is my industrial display flickering intermittently?

Flickering is commonly linked to power instability, signal interference, or a mismatch between your device’s refresh rate and the monitor’s native rate. Using high-quality shielded cables and stable power sources usually resolves the issue.

How do I prevent touchscreen failure in harsh environments?

Use touchscreens rated for IP65 or higher, apply anti-glare protective films, and choose capacitive screens tuned for glove or moisture input. Periodic calibration also ensures lasting accuracy.

What should I do if my screen suddenly dims or goes black?

This likely indicates backlight failure. Check the power supply and the LED driver circuit. For older models with CCFL backlights, consider upgrading to LED for better longevity.

Can I recalibrate a touchscreen that is responding inaccurately?

Yes. Most industrial systems include a calibration tool or menu option. Calibration aligns touch input with visual coordinates and should be performed regularly, especially after installation or system updates.

参考資料