Why Cleaning Your Clear LCD Display Matters

Even the best LCD panels can lose their edge if the screen is layered with oils, fingerprints, or dust. Here’s why regular, safe cleaning is a must:

- Image Clarity: Dirt and smudges reduce contrast and make visuals dull.

- Touch Sensitivity: For capacitive or resistive touchscreens, grime can interfere with touch accuracy.

- Hygiene: In shared or public-facing devices, cleaning minimizes germ transmission.

- Device Longevity: Using improper cleaners may erode coatings or damage polarizers.

Especially for industrial LCDs, clean screens mean safer operation, more accurate readings, and better user experience.

What You Need Before You Start Cleaning

Before jumping in, avoid the urge to grab glass cleaner or paper towels. Those are big no-nos. Instead, gather these screen-friendly supplies:

✅ Recommended Tools

| Item | Purpose |

|---|---|

| Microfiber cloth | Lifts dirt without scratching |

| Distilled water | Non-conductive, streak-free base liquid |

| 50/50 water + isopropyl alcohol (optional) | Disinfects without damaging coatings |

| Compressed air (optional) | Blows off loose dust, ideal for bezels |

Avoid:

Paper towels, rough cloths, ammonia-based cleaners (like Windex), window spray, or tap water—they can leave scratches or mineral streaks.

Step-by-Step: How to Clean an LCD Display Properly

Cleaning your clear LCD display doesn’t take long—but it must be done right. Here’s a simple, safe routine:

Step 1: Power Off the Device

Unplug it entirely or shut it down. This prevents electric shock, reduces risk of pixel damage, and helps you see dirt clearly.

Step 2: Dust First (Optional)

Use a can of compressed air to gently blow away loose dust or debris—especially around edges and ports.

Step 3: Use a Dry Microfiber Cloth

Gently wipe the screen in circular or vertical motions. Don’t press hard—light pressure is enough to lift off most dust and prints.

Step 4: Damp Clean with the Right Solution

If dry wiping doesn’t remove smudges:

- Lightly dampen (not soak!) one corner of a microfiber cloth with distilled water or the 50/50 alcohol mix.

- Wipe gently across the screen.

- Use the dry part of the cloth to buff dry and prevent streaks.

Step 5: Let It Dry Before Powering Back On

Give the screen a few minutes to air dry completely before turning the device back on.

What NOT to Do When Cleaning an LCD Screen

Some mistakes can cause irreversible damage. Avoid the following:

- Don’t spray liquid directly on the screen. Always apply to the cloth first.

- Don’t use window cleaner or alcohol above 70%. These can degrade anti-glare or optical bonding layers.

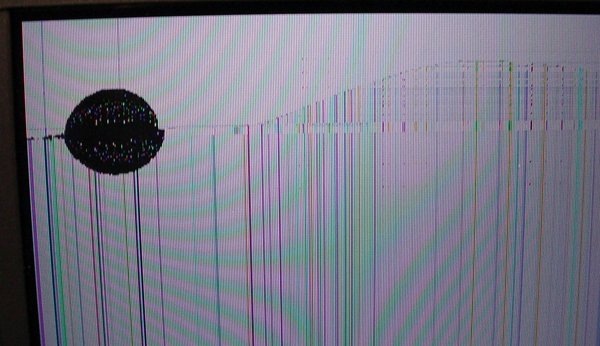

- Don’t rub hard. Excessive pressure may cause pixels to fail or dislodge internal layers.

- Don’t clean while the screen is on. Heat + moisture = risk.

Special Considerations for Industrial and Touch LCDs

For rugged displays in factories, kiosks, or medical devices, you may face grease, dust, or chemical residue. In those cases:

- Use anti-static wipes or professional-grade screen-safe solutions (ask your supplier for recommendations).

- For medical-grade LCDs, check if the display is rated for disinfectant wipes or alcohol pads.

- For optical-bonded screens, be extra cautious—scratches can’t be buffed out like with glass protectors.

FAQ: Frequently Asked Questions

Q1: Can I use eyeglass cleaner on my LCD screen?

Only if it’s alcohol-free and ammonia-free. Check the label. Otherwise, stick to distilled water or 50/50 isopropyl mix.

Q2: How often should I clean my LCD display?

For personal devices, every 1–2 weeks. For shared or industrial screens, daily or per-shift cleaning may be needed.

Q3: What if my LCD screen has a protective film?

Clean it as you would the LCD, but check if it’s removable or single-use—some films are not meant for long-term use.

Q4: Are LCD screen cleaning kits worth it?

Many are simply microfiber cloths + diluted alcohol. They’re fine, but not always better than DIY solutions.

Q5: Can I use 100% alcohol to clean my LCD?

No. Pure alcohol can strip coatings or cloud optical bonding layers. Always dilute to 50–70%.

Q6: How do I remove sticky residue from a screen?

Use a damp microfiber cloth with diluted alcohol and let it sit on the spot for a few seconds before wiping.

Reference Resources