Fundamental Structure of TFT-LCDs

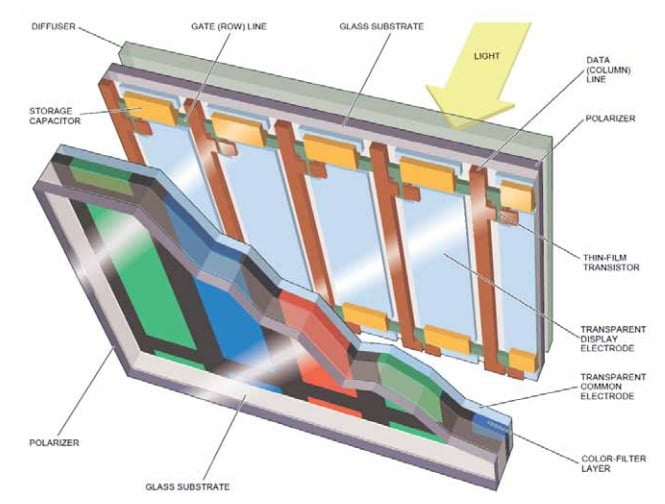

The intricate and precise structure of TFT-LCDs forms the foundation for their exceptional display capabilities. Key components include:

- Glass Substrates: Serve as the primary structural base, housing the liquid crystal and transistor elements.

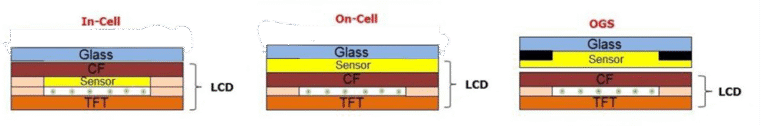

- Transparent Conductive Films: Typically made from indium tin oxide (ITO), these films function as electrodes, facilitating the application of electric fields to control pixel states.

- Liquid Crystal Layer: Situated between two glass substrates, this layer comprises liquid crystal molecules that align differently under electric fields, modulating light transmission.

- Color Filters: Positioned above the liquid crystal layer, these filters separate incoming light into red, green, and blue components, enabling full-color display.

- Thin-Film Transistor (TFT) Array: Each pixel is driven by a TFT, acting as a switch to regulate the voltage applied to the liquid crystal, thereby controlling light modulation.

Operational Principle of TFT-LCDs

TFT-LCDs operate based on the electro-optic properties of liquid crystals and the precise control provided by TFTs.

- Signal Transmission: Electrical signals are sent through transparent conductive films to the TFTs, which act as switches for individual pixels.

- Liquid Crystal Alignment: Activation of a TFT applies a voltage across the liquid crystal layer, causing molecules to align in a manner that modulates light transmission.

- Color Filtering: Light passing through the liquid crystal layer is filtered by color filters, producing red, green, and blue light components for each pixel.

- Image Formation: By controlling the voltage applied to each pixel, TFT-LCDs can display images with high clarity and color accuracy.

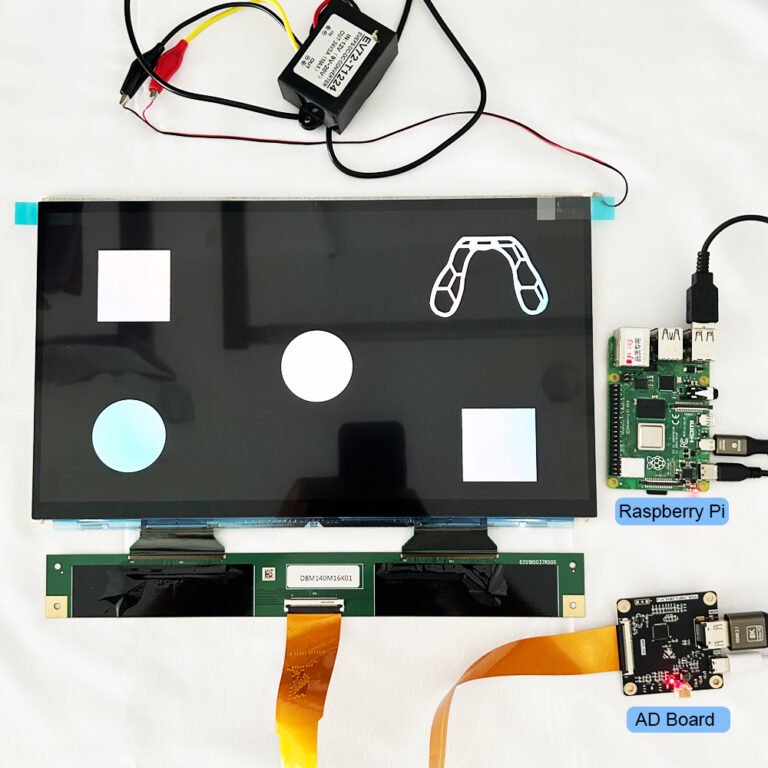

Thousands of products are available in our catalog.

Discover our wide range of products, including LCD-TFTs, OLED graphic and alphanumeric displays, LCMs, e-paper displays, barcode scanners (embedded, handheld, fixed mount), industrial monitors, industrial computers (carrier boards, COMs & SOMs, embedded systems, HMI panel computers, SBCs), capacitive and resistive touch screens, and accessories (development kits, connectors, controllers, FPC/FFC tapes, ZIF connectors).

Design Considerations for TFT-LCD Driver Systems

The design of driver systems is crucial for the performance of TFT-LCDs. Key considerations include:

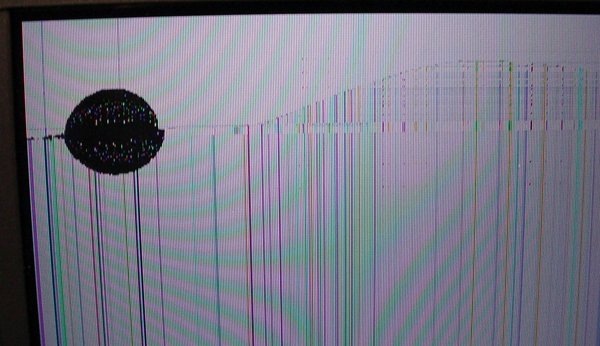

- Signal Integrity: Ensuring high-quality transmission of digital signals to prevent degradation of image quality.

- Timing Precision: Accurate generation of timing signals is essential to synchronize pixel activation and prevent display artifacts.

- Power Consumption: Optimizing power usage is vital, especially for battery-powered devices, to extend operational life.

- Thermal Management: Managing heat generation is important to maintain display performance and longevity.

- Electromagnetic Compatibility (EMC): Designing to minimize electromagnetic interference ensures compliance with regulatory standards and prevents disruption to other electronic devices.

- Reliability and Lifespan: Utilizing high-quality components and rigorous testing protocols helps ensure the display’s durability under various operating conditions.

- Cost Optimization: Balancing performance requirements with manufacturing costs is essential for market competitiveness.

Conclusion

The design and operation of TFT-LCDs are complex and multifaceted, involving a deep integration of materials science, electrical engineering, and optical physics. By understanding the structural components, operational mechanisms, and design considerations, manufacturers can develop displays that meet the evolving needs of consumers and industries alike. Ongoing research and innovation in this field promise to further enhance display technologies, offering richer visual experiences and broader applications in the future.