The Core Concept: What Makes an LCD Screen?

LCD stands for Liquid Crystal Display, a flat-panel display technology that uses a unique state of matter—liquid crystals—to modulate light. Unlike emissive displays such as OLED or CRTs, LCDs do not produce their own light. Instead, they manipulate backlight through controlled polarization and filtering to render visible images.

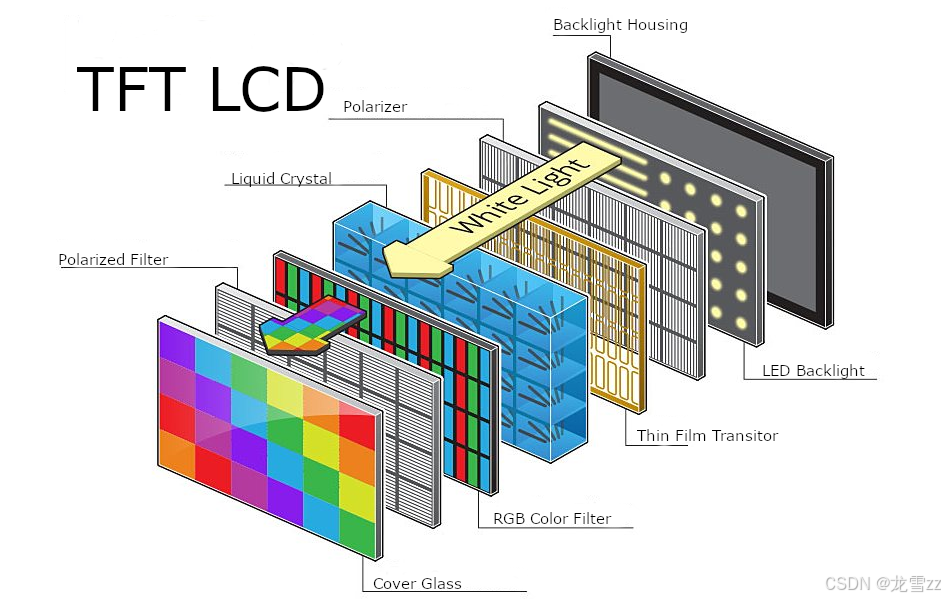

At a high level, every LCD panel consists of:

- A backlight source

- A liquid crystal layer sandwiched between electrodes

- Two polarizing filters

- A glass substrate embedded with thin-film transistors (TFTs)

- Color filters (for RGB rendering)

These elements work together to control how much light reaches each pixel—and what color it should be.

👉 Related reading: Structure and Driving Principle of TFT Liquid Crystal Display

What Are Liquid Crystals?

Liquid crystals are materials that exhibit properties between those of conventional liquids and solid crystals. In LCD technology, nematic liquid crystals are the most common type used.

Their key characteristic is that they can reorient their molecular alignment when exposed to an electric field. This change affects how light passes through the layer, allowing LCDs to control brightness and contrast at the pixel level.

Without an electric field, the molecules are aligned in a twisted structure, rotating the polarized light and allowing it to pass through the final polarizer. When voltage is applied, the structure straightens and blocks light, creating darker pixels.

The Role of Backlighting in LCD Screens

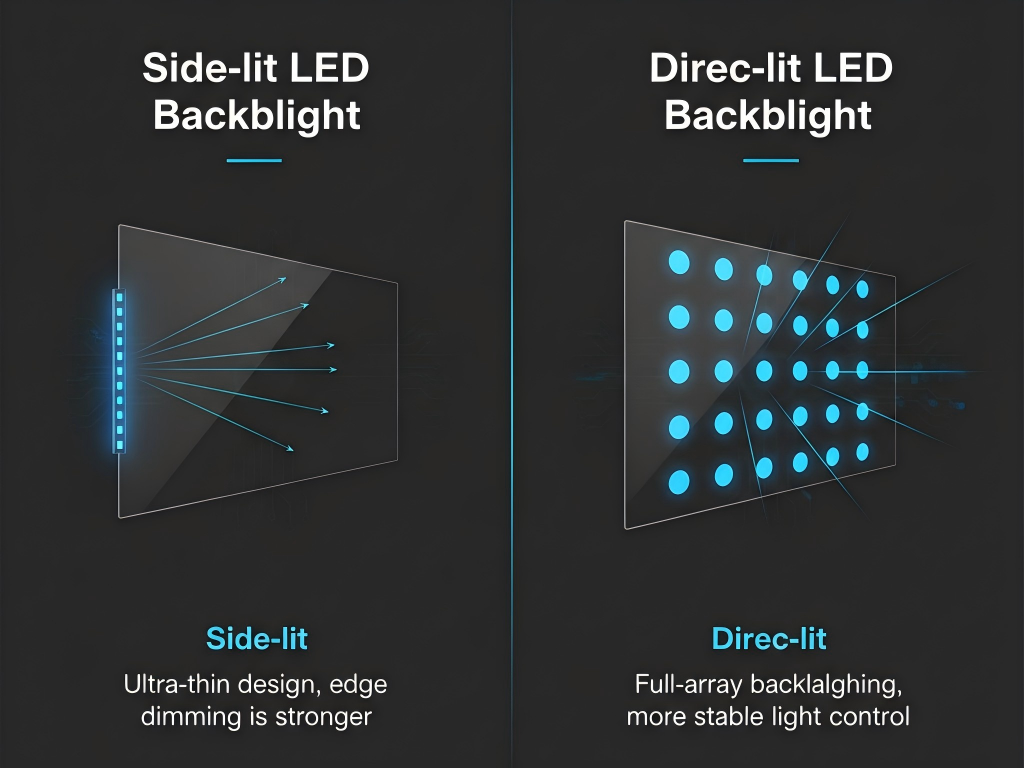

Since liquid crystals cannot emit light on their own, backlighting is essential. The backlight unit (BLU) is typically located behind the LCD cell and is composed of:

- LEDs (most commonly white LEDs)

- Light guide plates (LGP)

- Diffusers and prism sheets

The goal is to create a uniform, bright light field across the entire display. This light will then be selectively blocked or transmitted by the liquid crystals above, depending on the desired image content.

Modern LCDs use edge-lit or direct-lit LED arrangements, and some high-end panels employ local dimming to enhance contrast.

How Pixels Are Formed in LCD Displays

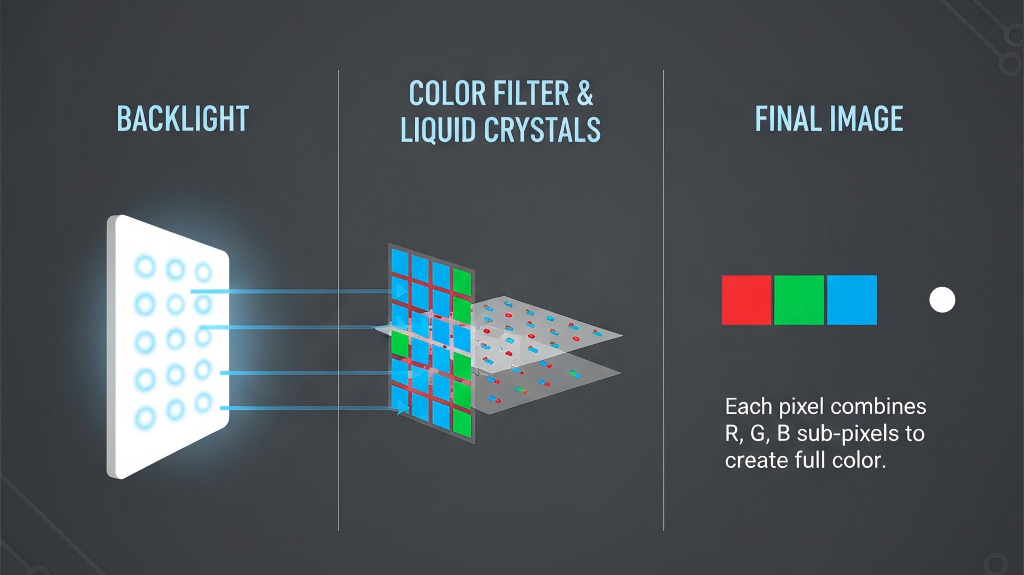

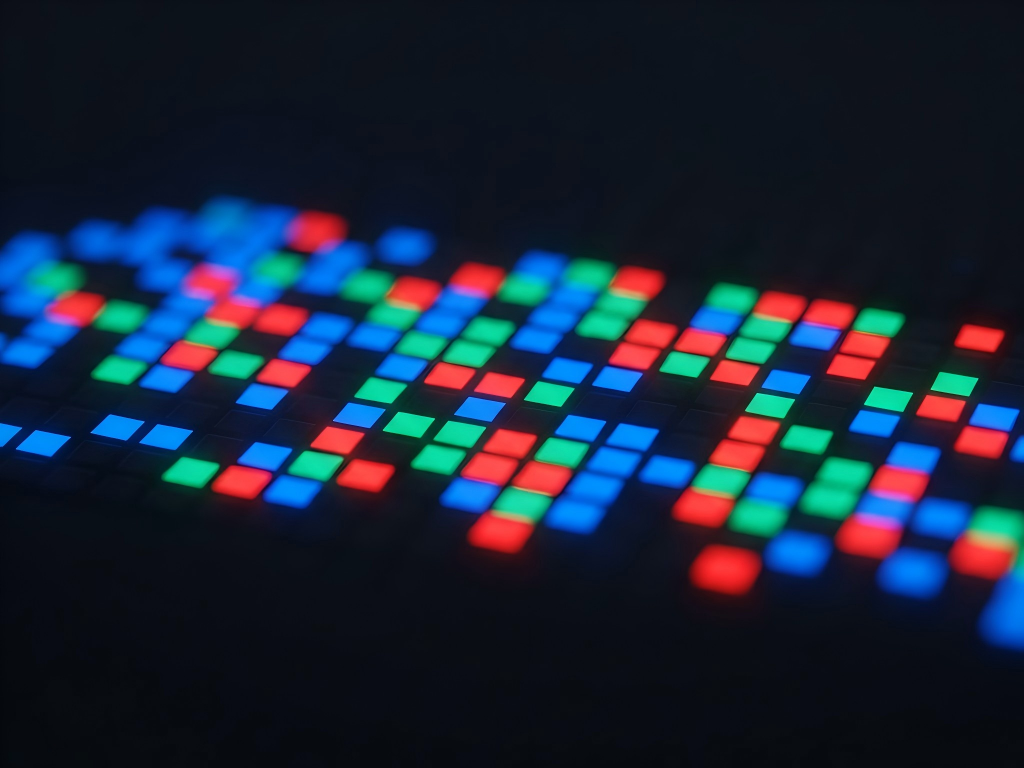

Each LCD screen is made up of millions of tiny units called pixels. A pixel in an LCD is not a single element—it consists of three subpixels: red, green, and blue. These subpixels are individually controlled to mix and create full-color output.

At the heart of pixel control is the Thin-Film Transistor (TFT) array, which acts like a grid of electronic switches. Each subpixel is addressed by its corresponding TFT, which regulates the voltage applied to the liquid crystals.

The more voltage applied, the more the liquid crystals align and block light—making that subpixel darker. Conversely, less voltage allows more light through. By varying this across subpixels, LCDs can display millions of color combinations.

How Color Filters Create RGB Output

Since the backlight is typically white, color filters are necessary to produce full-color images. These are patterned across the display in a fixed sequence—usually red, green, and blue stripes or delta arrangements.

Each subpixel sits beneath a color filter, and only allows light of that specific color to pass. By combining different brightness levels from the red, green, and blue subpixels, the display can render any color perceived by the human eye.

For instance:

- Red subpixel = full voltage → blocks light → appears dark

- Green subpixel = low voltage → passes more light → appears bright

- Blue subpixel = mid voltage → moderate light → mid-tone

Together, the eye blends these into a single color pixel—perhaps yellow, purple, or white.

The Role of Polarizing Filters

Polarization is essential to LCD operation. Two polarizing layers—one at the front, one at the rear—are aligned perpendicular to one another.

In the off state, the liquid crystal layer twists the light’s polarization so it passes through both filters. When voltage is applied, the crystals untwist, blocking the polarized light at the second filter. This mechanism allows the display to selectively dim or brighten subpixels based on electric input.

In “normally black” panels (common in IPS displays), voltage activates brightness. In “normally white” panels, voltage blocks light. The choice depends on application needs for contrast and power behavior.

Different Types of LCD Technologies

Several LCD panel types exist, each optimized for specific needs:

TN (Twisted Nematic)

- Fast response, low cost

- Narrow viewing angles

- Ideal for entry-level monitors, low-cost applications

IPS (In-Plane Switching)

- Excellent color consistency and wide viewing angles

- Common in mobile devices, professional displays

VA (Vertical Alignment)

- High native contrast, deeper blacks

- Used in TVs, control panels

Transflective LCDs

- Reflect ambient light + use backlight

- Ideal for sunlight-readable applications (e.g., outdoor instruments)

Each type uses the same liquid crystal principles but alters molecular alignment and electrode geometry to suit different viewing and power conditions.

👉 Related reading: What are the differences between TN, VA, and IPS?

Frequently Asked Questions

What is the role of polarizing filters in an LCD screen?

They control the passage of light based on orientation. LCDs use two crossed polarizers and the liquid crystal layer to rotate or block light, enabling brightness control at the pixel level.

Why is backlighting necessary in LCD screens?

Liquid crystals don’t emit light. Backlighting provides a uniform light source that is selectively modulated to form images. Without it, the screen would remain dark.

How does an LCD screen produce different colors?

By combining red, green, and blue subpixels—each with its own color filter and brightness control—LCDs can mix light in different intensities to form full-color images.

What are the advantages of LCD technology over other displays?

LCDs are energy efficient, cost-effective, and mature. They offer good brightness, sharpness, and long lifespan, especially when paired with LED backlights.

What are the different types of LCD screens?

TN, IPS, VA, and Transflective are common types—each suited for different use cases ranging from budget monitors to sunlight-readable displays and high-end color-accurate screens.