Facing a bottleneck in your Embedded Display Project?

Don’t let complex integration or supply chain issues slow your time-to-market. Book a free consultation with the RJY expert team for tailored design and manufacturing support.

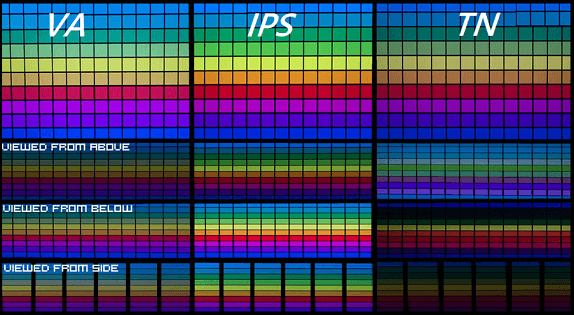

TN panels are the oldest and most basic form of LCD technology. The liquid crystals in these panels twist when an electrical current is applied, altering the way light passes through them. This results in a relatively fast response time, making TN panels ideal for fast-moving content, such as video games or high-performance computing tasks.

However, TN panels are known for their poor color accuracy and narrow viewing angles. The colors tend to look distorted when viewed off-center, and the panel’s brightness can degrade significantly at wide angles. As a result, TN panels are not the best choice for professional design, color-sensitive tasks, or collaborative environments.

Despite these limitations, they serve well in cost-sensitive, low-interaction displays.

Best For: Cost-sensitive displays where speed is more important than color accuracy.

VA panels take a different approach to the arrangement of liquid crystals. When unpowered, the liquid crystals are aligned vertically, blocking light. However, when a voltage is applied, the crystals rotate to allow light to pass through. This unique alignment enables VA panels to achieve some of the best contrast ratios in the LCD market, with deeper blacks and brighter whites.

While VA panels provide excellent contrast, they still suffer from limited viewing angles, though they tend to outperform TN panels in this regard. The color reproduction on VA panels is also typically better than that of TN panels, but still not as accurate as IPS panels.

Vertical Alignment (VA) LCDs deliver exceptional contrast ratios—often exceeding 3000:1—thanks to their ability to block light more effectively. This makes them suitable for industrial environments with low ambient light, as well as applications where black level clarity is crucial.

Best For: Medical imaging, smart appliances, home automation, and semi-outdoor environments.

IPS panels are the most advanced LCD technology in terms of color accuracy and viewing angles. The liquid crystals in IPS panels are aligned horizontally, allowing for better light control. As a result, IPS panels maintain consistent brightness and color reproduction across a wide range of angles, making them ideal for applications that require precise color accuracy and wide viewing angles.

Due to the more complex manufacturing process, IPS panels are often more expensive than TN or VA panels.

For industrial LCD display screens that require high visual clarity, accurate color, and wide viewing angles, In-Plane Switching (IPS) panels are the gold standard. Though more expensive, IPS technology ensures that touch interfaces and color-sensitive applications remain consistent across the entire screen surface.

Best For: Industrial HMIs, medical monitors, design systems, and displays requiring color fidelity.

Let’s now look at how TN, VA, and IPS panels compare in various key aspects:

| Aspect | TN Panel | VA Panel | IPS Panel |

|---|---|---|---|

| Color Accuracy | Poor | Better than TN, but not as accurate as IPS | Best color accuracy |

| Viewing Angles | Narrow (distorted at angles) | Wider than TN, but still limited | Very wide (consistent from all angles) |

| Contrast Ratio | Lower | High, deep blacks | Moderate to high |

| Response Time | Fast | Slower than TN, but still decent | Slower than TN, but suitable for most tasks |

| Cost | Affordable | Mid-range | Expensive |

| Best For | Gaming, budget monitors | Home entertainment, medical displays | Professional work, design, medical applications |

For businesses developing industrial LCD display screens or custom TFT modules, understanding the strengths of each LCD panel type is critical:

By integrating the right panel into your customized display solution, you ensure better performance, durability, and user satisfaction.

Here’s what to evaluate when choosing a custom LCD panel type:

We support projects with custom resolutions, interfaces, brightness tuning, and mechanical design.

👉 Related reading: How to Choose the Right LCD Touch Type for Your Project

Q1: Which LCD panel is best for an industrial control HMI?

A1: IPS is ideal for high-visibility HMIs, offering color accuracy and wide angles. For basic numeric control panels, TN may suffice.

Q2: Can I use VA panels for outdoor kiosks?

A2: Yes—especially when paired with high-brightness backlights and anti-reflective coatings. VA’s deep contrast supports readability in shadow-heavy environments.

Q3: Are TN panels suitable for industrial automation?

A3: Yes, for simple interfaces and budget-constrained projects. However, they’re not ideal for color-sensitive or multi-angle usage.

Q4: Do IPS panels support glove touch?

A4: With proper touch sensor tuning, yes. We provide custom touch tuning services for capacitive overlays to support glove operation.

Q5: Can you customize TFT LCD modules based on application?

A5: Absolutely. We offer panel selection, bonding, touch integration, and enclosure customization for diverse verticals—medical, factory automation, retail, and more.

Reference Resources